Space Elevator - Development Visions

(Eric Hunting - hunting@tigger.jvnc.net - 9/4/02

I've been developing a vision and scenario for an SE project and I thought

I might share it with the group. It might be useful in focussing discussions

if there was a specific project scenario whose components could be individually

analyzed.

System components:

Initial Tether and Deployment Rig:

The initial tether would be fabricated on earth and would consist of a

very thin nanofiber cable or ribbon -around a centimeter thick/wide at the

ends- which would be carried whole to orbit as a pair of coils. The coil

carrier would consist of an octagonal space frame truss girder made with

a ball-socket node truss system -such as the one Star*Net Corp. developed

for the ISS but which was shelved by NASA- inside which the tether would

be coiled in two coils in an outside-in manner like rope coiled in the storage

space on a sailing ship. Two deployer rigs are mounted inside the ends of

the truss along with terminator modules; instrument packages in a capsule.

The 'up' module would house sensors to aid deployment tracking, monitor tether

electrical/electrostatic potential, and so on. The 'down' module would feature

a streamlined capsule with telemetry transponders and small deployable fins

-a set of small square ailerons on thin pop-out struts- which allow it to

be steered in winds. Between the two coils is a clamp rig with neprene sheathed

clamps which grip onto the tether. On the outside of the truss would be

retrofit attitude control modules, deployable solar panels, a command and

telecommunications package, and possibly a light telerobotic arm.

This structure, which I imagine as approaching the size of a Shuttle EFT,

would be launched whole using a launch system which is retrofit to its sides.

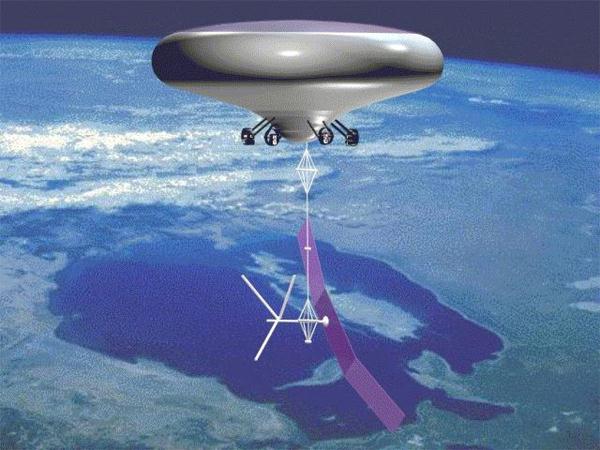

One launch concept I favor is the use of a dirigible airship assisted launch

system. This would take the form of a large ballonette hull with a lenticular

ovoid shape (think a rounded edge disc stretched into a slender oval) made

from a space frame of pneumatic struts. (pressurized membrane tubes with

socket connectors on their ends. Made from the same material as the tether

and highly pressurized, these would be as strong as solid aluminum yet an

order of magnitude lighter) It would include its own short duration fuel

cell power supply and ducted fan thrusters intended for attitude control

but no propulsion at speed.

The truss package would attach to this hull like a gondola. Attached to

the flanking sides of the truss package would be one or two conventional rocket

boosters, most likely solid fueled. The airship hull would lift the launch

package to a very high altitude, transitioning from gas lift to vacuum lift

at high altitude in order to give the vehicle the maximum possible altitude,

hence the use of a dirigible structure rather than a simple blimp. Vacuum

lift is not possible with existing materials at sea level air pressures

but at very high altitude where air pressure is very low a dirigible made

with conventional materials could shift to vacuum lift, discharging lift

gas with altitude as normal high altitude balloons do but continuing until

evacuated, gaining about an extra 10-20% in altitude. Upon reaching this

maximum altitude and positioned for an equatorial launch, the vehicle would

ignite its rockets, ramping up comparitively slowly in speed. Upon reaching

sufficient airspeed, the dirigible ballonette is jettisoned and the vehicle

accelerates to a GEO velocity, later jettisoning the spent rockets. The

dirigible hull could be recovered for later re-use but the system is generally

not intended to be reusable.

The point to the airship assist is to get the truss package to an altitude

where there is very little atmospheric drag so that it can be launched without

the added mass of a streamlined skin. There is a small but not entirely

insignificant savings in rocket power from eliminating the drag encountered

from sea level but since a conventional vertical launched rocket only sees

maximum drag for a tiny amount of time during launch, that by itself would

not justify this approach. What it's really about is saving net vehicle mass

by using simpler and lighter construction. The less sheering force stress

from drag, inertia, and engine vibration the vehicle must withstand during

acceleration the lighter and less robust its construction can be. Thus it

becomes practical to use simple modular components for everything and to

eliminate the extra mass of a streamlining skin. Space structures rarely

need the robustness of construction that is typically employed. This robustness

is largely just to compensate for the stress the structures endure during

launch. Reduce that stress and you reduce the whole mass of the system. Also,

conventional rocket engines only operate efficiently in a small range of

air pressures and for a sea-level launched rocket a lot of efficiency is

lost because the engines must transition between such a wide variation in

air pressures. Launched at high altitude, a rocket engine can be optimized

for near-zero air pressure alone, thus leading to a simpler lighter engine

with higher efficiency, which means less fuel and thus less net mass.

So basically this 'gimmick' allows you to build a whole launch system from

cheap ultralight space frames and simply assembled modular retro-fit components

that normally might not tolerate the conditions of launch. Plus, you get

the ability to launch a relatively large and fragile payload with the minimum

of physical stress, the ability to abort and recover the whole payload package

at any point up until the ballonette jettison point, the freedom to deploy

a launch vehicle from anywhere without elaborate permanent ground facilities

using the airship component as a shuttle to the equator (remember, the bulk

of launch costs are on the ground, not in the vehicle), and you avoid launch

delays associated with weather because in the stratosphere there is none.

The package could also be launched in a more conventional manner, using

two to four booster rockets and an added nose cone, tail blast sheild, and

aluminum streamlining skin on the spool package. The carrier space frame structure

would have to be tougher and much more expensive overall but its basic form

could remain the same, though a lot of the added 'packaging' has to be dismantled

on orbit using robots. A likely configuration could be a ring of Zenit boosters

or similar simple rockets.

GEO Upstation:

The space frame truss used for the tether carrier package is the foundation

of the initial GEO facility and this role is largely the reason for its

space frame based design. This structure would serve as an expandable scaffold

onto which all the later facilities in orbit would be retrofit simply by

plugging into the space frame nodes or clamping onto its struts. Similar

to the MUOL (modular unmanned orbital laboratory) concept, it would host

a 'backplane' system which integrates fiber based communications, power,

and thermal radiant fluid supply using a utilities module that retrofits

to the inside of the truss and allows structures retrofit to its outside

to plug in via standard ports, just like components plugging into the backplane

of a computer system.

The communications system for the Upstation backplane would be based on

a pair of IP networks using a conventional microwave link to the Downstation,

one dedicated to the systems management of the Upstation, the other a 'community'

network shared -through VPN subdivision- by Upstation lease space clients

for communication between their individual service packages/modules. The

standard architecture of the Upstation's systems would be based on the use

of integrated Web controllers. These are microcontrollers which have a built-in

single-chip Web server which presents a virtual control panel that can be

accessed from any point in the system's network. Technicians manage the station's

systems and client packages by paging through the virtual control panels

or by using hierarchical control panels which, through a single interface,

manage multiple controllers using the same Java messages. Complex automated

sequencing is also possible in this way, but using independently running

sequencer programs running on master management computers on-board or on-ground,

allowing for the same technology to also be used as the basis of complex

launch sequencing, experiment management, or later spacecraft operation.

This can be employed to reduce the development and operational costs for

new launch systems, like dirigible hybrid vehicle proposed above. In essence,

the Upstation is a kind of MUOL. (for background on the MUOL concept see;

http://www.distant-star.com/issue13/jan_2002_leo_or_geo.html

)

This core truss must freely expand in width with the incremental expansion

of the thickness of the tether as well as host a perpendicular planar space

frame on which lease space components can be located with a clear terrestrial

(or less frequently a clear space) view. Construction of this plane space

frame would be one of the first orders of business for the Upstation and

part of the initial truss package could include a telerobotic manipulator

arm similar to the MK Robotics Canada Arm deployed on the ISS to facilitate

its assembly. Thus the geometry of the core truss must synchronize with the

geometry of the surrounding plane truss. This means that the core truss must

fit into a 'tesselation' of the plane truss derived from the same component

geometry. Thus it will likely use a cubic space frame based on two strut

lengths that allows for an octagonal core truss to intersect a rectangular

planar space frame. This would be consistent with the cubic unit module geometry

for lease space components envisioned in the MUOL concept. The size of the

intersecting octagon can increase in face size in units equal to the width

of the cubes of the planar space frame. Thus expansion of the core truss

would be performed simply by clearing any functional plug-in modules at the

intersection of the core and plane trusses, building a new core truss around

the old one, and then disassembling the old core truss from inside, the old

parts recycled by expansion of the plane space frame. This process can be

conducted indefinitely, no matter how large the tether becomes. But as the

structure grows the plane truss will need to be thickened as it increases

in area to increase its rigidity. Thus after several stages of growth the

core truss will becomes completely absorbed into the plane truss, which will

have thickened to become a vast rectangular space filling frame through which

the tether passes.

Manned habitat structures would take the form of trans-hab-like inflatable

modules surrounded by the spaceframe to which radiation and meteroid sheilding

panels would be attached, all designed to be assembled on orbit from densely

packed modular parts that would be relatively easy to convey along the rudimentary

tether. This is the most efficient approach to habitat construction, since

there is technically no reason for sheilding materials to be integral to

a pressure hull and with membrane structures capable of packing exceptionally

large habitat volumes into very compact packages. (a space station based

on transhab technology could fit the entire inhabited volume of the finished

ISS into a single Shuttle payload. In fact, this was planned early in the

Shuttle program but shelved. Smaller transhab modules similar in size to

the existing ISS modules should readily fit within the payload capacity of

second or third generation climbers)

[Transhab prototype design]

Most likely, the initial GEO Upstation would host a 'crew' composed exclusively

of compact teleoperated robots, the initial tether conveyors -due to the

small scale of the initial tether- limited to carrying components of small

mass. Non-pressurized shelters in the form simple shielded box enclosures

and pressurized shelters in the form of small modular pressure vessels with

external support equipment would be the typical facilities for a long time.

With communications latency low for a GEO facility, telerobotics is relatively

easy to implement and so human workers in space would be unnecessary, and

not cost-effective in any case. Indeed, the only commercial space activity

that actually requires any manned facilities is tourism, though once the

full scale elevator transport is in place the ease of transport may make

human workers more cost-competitive.

[NASA Ranger telerobot assembler prototype]

It is also possible that manned habitat facilities at this GEO Upstation

could be provided by the hollow fuel tanks left from the original tether

carrier package boosters -assuming they were LH/LOX fueled. The tanks could

be pre-adapted for this purpose with pre-installed partition and frame sockets,

hatches, and windows behind conformal tank skin plates. However, that's much

extra mass to carry to GEO and with the GEO station remaining unmanned for

a long time these would have to remain mothballed on orbit for many years.

Later generation Upstation facilities would become increasingly integrated

into the structure of the tether itself, depending on which of the tether

development approaches noted below is used. Manned facilities would evolve

to become incorporated into the vast volume of the tether at its thickest

center portion, using a matrix of internal channels which, by virtue of

the tether composition, already offer an impermeable structure that need

only modular caps on the exposed surface channels to make them pressure-tight.

The considerable mass of the tether material itself would be relied on as

radiation shielding. In the case of the multi-strand approach noted below,

the same transhab-like structures would be used but suspended in the matrix

of discrete tether strands rather than attached to an external space frame.

External systems -primarily communications, solar and radiator panels, solar

dynamic systems, and spacecraft assembly/service 'creches'- would be attached

to unused elevator rails in a fashion similar to components on a T-slot

profile beam or may rely on external truss booms clamped on in the same

way or extending from the surface ends of interior channels.

Tether Climbers:

Initial transport along the tether and incremental addition of fiber strands

would be based on 'climbers' that use simple membrane LTA lift cells for

initial lift then traverse the cable by traction drive using polyurethane

wheels when they reach the stratosphere. These small vehicles would take

the form of a segmented tensegrity (cable-stayed) truss chassis to which

the drive hardware is bolted facing the inside and payload, lift cells, and

drive/control components on quick-release locks on the outside. Vehicle mass

would be greatly minimized using a tensegrity truss structure -exploiting

the same materials the tether itself is made from in the form of cable stays

and composite compression rods. The vehicle would be held together by tiny

explosive bolts which are intended to snap its cable stay links and cause

it to break apart completely in the event of it getting stuck on the tether.

These climbers would have small payload capacity and could be powered either

by inductive energy from the cable, by photovoltaics, or beamed power using

IR laser (feeding IR PV cells) or microwave beam. In the case of these beamed

energy arrangements, the use of a lenticular (disc shaped) LTA hull around

the climber would provide support for these power systems energy collectors,

either covered by flex-cell IR PVs or being covered with an elastomeric laminate

rectenna array for microwave pick-up. The round shape also serves well as

the basis of a coil storage platform, allowing the climber to add fiber to

the tether from another outside-in coil surrounding the tether coiled inside

the chassis truss much like the tether was originally coiled on the GEO truss

package.

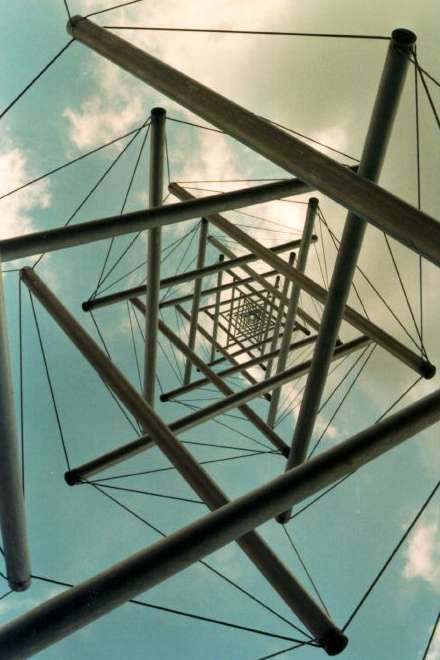

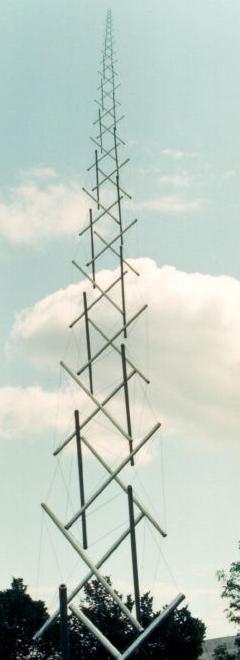

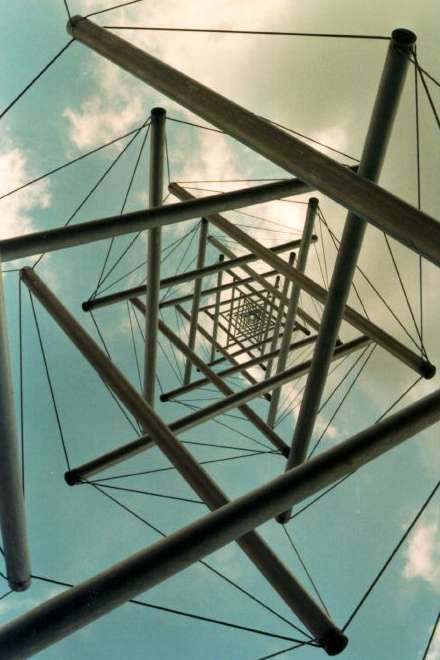

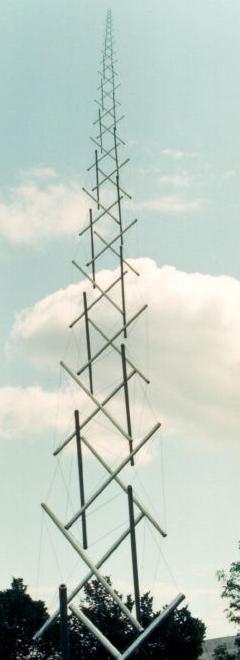

[a tensegrity truss mast, made as sculpture]

A possible alternative to the use of polyurethane wheels in the climber

drive mechanism could be a kind of dual tractor band. This would consist of

two flat soft plastic (neoprene?) bands on carriers similar to a tank wheel

track or conveyor belt which sandwich and clamp the tether between them when

engaged. The advantage of this system would be a very high friction interface

between drive and tether that eliminates slippage that would result in wear

on the tether fibers -important considering the hundreds of thousands to

millions of trips these simple climbers would make during the incremental

construction of the tether. However, it could be a much slower and heavier

drive mechanism.

There is also a possibility of exploiting electrokinetic thrust 'lifter'

systems for a climber drive if the tether itself is capable of providing

the high voltage from electrodynamic induction this propulsion requires.

The ultralight tensegrity climber chassis would be well suited to this kind

of propulsion. At high altitudes and in space this would require the use

of ducted field grids with some means of intake compression like fans and,

above the atmosphere, a supply of compressed gas propellent. This added drive

hardware mass could be a problem for this concept. If viable, this would

offer a very high speed non-contact way of climbing the tether using solid-state

hardware with a potentially supersonic speed and 5:1 ratio of payload to

drive mass. (assuming externally provided power... EK lifters would be completely

infeasible if they had to carry their own power source) These would be too

fast and light to function as a tether fabricator. They would, instead, be

limited to quick light transport alone -and very light transport at that.

Whether these devices could work for a full-scale elevator is unknown. At

present the technology is at a Wright Bros. level of development with largest

model vehicle ever built only a couple meters long. So it's safe to speculate

for a small climber but perhaps not for a large elevator car.

Full scale elevator system:

This will likely emerge quite some time after the initial tether deployment

due to the period of time required to incrementally thicken the thin initial

tether to a scale where it can bear the necessary mass. The target form

factor for the full scale elevator will likely derive from existing terrestrial

transportation systems. This means that dimensions will likely derive from

the dimensions of the largest standard marine shipping container; 40'x8'x9.5'.

Indeed, it is possible that the elevator design would use a variation of

the standard marine container built of nanofiber composites and attaching

to a modular elevator chassis via quick-connect locks allowing for direct

intermodal transfer. Thus a fair guestimate for a basic minimum elevator

car size would be 50' tall by 15' wide.

The full scale elevator will most likely rely on a linear motor drive using

magnetic isolation (keeping it from contacting the track it climbs) and

will assume one of three likely configurations depending on which tether

structure is chosen; monorial, mono-cable, and tubular. The monorail configuration

relies on an external track either in a T-beam or T-slot form, the drive

chassis surrounding the track in the case of the T-beam or riding whole or

partly inside the track in the case of the T-slot. The elevator car rides

parallel to the track and is readily accessed externally. Most SE schemes

have been based on this elevator configuration but its drive design is complex

because of asymmetric axial loads on the track.

The mono-cable scheme relies on the use a tether strand dedicated exclusively

to the task of carrying one elevator car. The tether functions as the track

and the drive chassis surrounds it, being either fully enclosed by the elevator

car or with the car divided into modular components attached and balanced

around the core chassis. This configuration derives from that of the simple

climber and would have the simplest drive mechanism. But the configuration

is complicated in terms of cargo handling unless the net car diameter is

very large -perhaps 50' wide. There are also failure scenario issues with

this configuration, which will be discussed later. Car size is also limited

by the scale of its tether track, regardless of the scale of the whole tether

structure.

The tubular configuration relies on a surrounding tube as a track with

the drive system surrounding the vehicle. This is a very simple drive configuration

which offers simple asymmetric axial load compensation. But this approach

requires the tether to assume a relatively complex corrugated form with

multiple tubes. This, in turn, requires perpendicular channels to be formed

to access the elevator car or for the lower tether terminus and mid section

to be 'spread' apart into multiple strands so that the interior tubes are

opened up for whole-car access. A fixed elevator car size regardless of the

ultimate tether scale is another limitation.

Tether fabrication and structural approaches:

Incremental expansion of the tether would be performed by laminating thin

fiber tape windings to the cable -flat or round- using slow climbers. Each

added tape winding represents only a miniscule mass compared to the cable

itself, allowing the applicator climber to travel first to the GEO point,

or it's last application point, then use gravity (or centripetal force on

the above-GEO tether length) to pull it along as it laminates new material

to the tether. Later tether material fabrication would shift to the Upstation

which makes the transport of building material easier since it can be piped

to the Upstation through a hollow core tether in the form of carbon monoxide

gas. Each phase of lamination consists of layering short strips over the

middle tether regions followed by progressively longer strips to the ends.

This insures that the tether is made thicker toward the middle than at the

ends, since the middle experiences the highest degree of tensile force. This

laminating is a necessarily slow process, each new layer of tether material

taking perhaps months to apply. This creates a certain conflict between the

revenue-generating use of the tether and its incremental expansion which,

of course, expands the payloads the tether system can communicate between

Earth and space. The solution is to develop the tether structure so as to

support multiple simultaneous uses; material laminating, retrofit structural

support, and elevator track.

There are three likely full-scale tether structural approaches; monolithic,

corrugated, and multi-strand. The monolithic full-scale tether -the type

most commonly suggested in SE schemes- is based on a prism structure with

polygonal cross section which is intended to allow different prism faces

to assume seperate functions. The initial tether could be flat or round but

in either case would evolve to assume a 4, 8, 16, 32, etc. sided section.

Sides are expanded alternately, using a variation of the climber which travels

on one or two tracks while laminating the face adjacent or in-between. As

each face completes a phase of laminated expansion it is 'finished' by the

addition of a conformal elevator rail structure made of the same tether material.

This might take the form of a T-beam which is stripped off or fully absorbed

into the tether with successive expansion or a T-slot which is closed off

with each phase of expansion, producing a relatively thin corrugated structure

in the tether section to be used as pipelines and power/communication vias.

When not being worked on by a laminator climber, each free side becomes

available to carry either an elevator vehicle or host demountable structures

which clamp onto the track.

The upside to this approach is that the fabrication process is relatively

streightforward. The downside is that the initial tether has to be expanded

to a pretty large size before it assumes a polygon side width large enough

to host a useful elevator track. Until then, the tether project is limited

to alternating cycles of tether expansion and tether transportation -since

it's complicated for climbers using continuous contact traction to pass

over each other on the tether. It also can't host any intermediate station

points, again because the climbers can't easily pass over the station structures

unless they are very large, wide, and light. And even when it can start supporting

these structures, they would be limited to very narrow forms in order to

allow enough room for elevators and climbers to pass by them.

The corrugated tether approach is based on the use of an internalized elevator

system and hence the tether would assume the form of a series of parallel

hollow tubes as it grows. This would be done by first expanding the initial

tether monolithically until it can support the mass of ultralight inflatable

super-pressure forms made of the same tether material which the climbers

tape over to make the hollow space. The balloons are then cut away from the

inside to create a shaft into which elevator track hardware is retrofit.

Once the first tube is complete, it can host its elevator internally while

externally the laminator climbers continue to expand the structure uninterupted.

Any number of parallel tubes can thus be formed in place to support different

jobs; elevator, pipeline, communications vias, internal habitat space.

There are a number of compelling advantages to this approach. First, it

is easier to engineer a linear motor drive when the drive mechanism is arranged

radially around the vehicle. This is because the axial loads around the

vehicle would be uniform. With an external track vehicle, there's a difference

in axial loads between the top and bottom of the vehicle which the drive

carriage or aerodynamic form of the vehicle system must compensate for in

some way. This is because as the vehicle accelerates drag on the capsule

plus gravity and intertia create a shearing force that wants to pulls the

top of the car away from the tether while the bottom is alternately pushed

in. And when the vehicle decelerates via breaking this force is reversed.

This is not a problem for the internal elevator which is completely surrounded

by its drive mechanism and under a radially uniform drag, gravity, and inertia

force. Such an elevator system would easily translate into a mass accelerator

launch system, allowing the elevator capsules to be launched from the end

of the tether with massive acceleration.

Another advantage is that as the tether structure increases in volume tubes

at the center enjoy increased radiation shielding by the material of the

tether itself. This means that one can use core tubes for human transport

and outer tubes for materials transport while still having the same basic

elevator vehicle and without spending extra mass on sheilding for human passengers.

Related to this is the fact that a very thick tether with numerous redundant

tubes may also allow virtually all human habitat space needed for the GEO

station to be internal to the tether itself rather than based on external

structures. Numerous parallel tubes also provide numerous conduits for supplying

all kinds of gaseous materials, power, communications, and other applications.

With a little imagination, some very interesting and novel applications

for these tubes could be devised. For instance, a tube could be used as

a huge tornado tower by simply leaving its end open to space. The difference

in temperature between sea level and space create a vortex along its length,

which would be tapped as another source for power via in-line turbines or

just light field coils exploiting the magnetohydrodynamic potential of the

moving air. (insignificantly small in a small tunnel but along the whole

length of the in-atmosphere portion of the tether potentially a lot of energy)

Similarly, linked pairs of tubes could be used to create a thermal cycle

between the cold Upstation side and the warm Downstation side, creating a

continuous updraft that could produce power or be used simply as a means

to pump gasses to the upstation. If the updraft were powerful enough, it

might actually power a pneumatic elevator.

The downside to this structural approach is that the fabrication is more

complicated and, with no external rail system to travel on, the laminator

climbers must increase in width to accommodate the increasing thickness

of the whole tether. Intermediate stations must retrofit temporarily inside

the space of unfinished tube sections and cannot expand outside the tube

volume in order to allow the climbers to pass over them. Window views are

eliminated inside the elevator and limited to the ends of cross-shafts for

internal habitat structures, those these can potentially be quite large.

The size of elevator cars becomes permanently fixed by the dimensions of

the tubes, compelling the initial tube to assume the largest reasonable dimension

for an elevator cab, and it is not possible to transfer payloads which might

be low mass but bulky and larger than can fit inside the tube. Transfer between

tube and station becomes a complicated affair, especially at the Upstation

where the great thickness of the tether means that long access channels

must penetrate the tether. Or the tether must be spread apart into multiple

sections to allow for numerous access channels.

The multi-strand approach is based on the idea of using multiple duplicates

of the initial tether in order to create a network of thin tethers rather

than a single tether. This is achieved by assembling or launching duplicates

of the same tether carrier package used in the initial deployment, attaching

them to the Upstation truss structure, and using climbers to guide the new

tethers up and down with the adjacent tether serving like a track. Technically,

there is no particular structural reason why the SE tether needs to be one

monolithic cable. A matrix of cables will bear the same net loads.

The primary advantage of this approach is that the SE project could quickly

support simultaneous transportation -and hence robust industrial applications.

Multiple tethers make it easy for the project to support multiple simultaneous

activities, each individual tether dedicated to a single task. Fabrication

of tethers by lamination is MUCH faster when it can be done in a factory

setting rather than on the surface of a deployed tether. So a matrix of tethers

would be faster to make than one monollithic tether of the same mass. And

by using a matrix of thin tethers as scaffolding and materials transport,

a very large tether can be simultaneously fabricated and deployed within

them -the scenario envisioned by Arthur C. Clarke in Fountains of Paradise.

Alternatively, multiple initially independent tethers can be mechanically

bound together to make a thicker structure, either monolithic or corrugated.

The use of the tether itself as a station structure becomes more practical,

the matrix of tethers serving like the system of columns in a typical skyscraper

onto which truss supports can be simply clamped. The SE could readily evolve

into a kind of superskscraper this way. Full scale elevator systems can evolve

more directly from the initial climber technology, the engineering greatly

simplified by using the whole tether as a centralized track and drive mechanism.

Upgrading to superior tether materials is a simple process, as individual

tethers can be obsolesced and removed with the rest of the SE structure remaining

unaffected. Likewise, failure of individual tethers would not effect the

rest of the structure, except where its failure causes damage to retrofit

structures.

The downside of this approach is that low net load capacity of small individual

tether strands would demand any fixed retrofit structures to be of extremely

low density, which may limit their usefulness. Likewise, limited to a thin

tether moving through its center as a track, elevators for this type of

system may always be limited to extremely low capacities and face cargo

packaging problems from the obstruction of the center drive structure. Instead

of a unified car structure, a modular structure where a core truss drive

chassis is surrounded by relatively small cylindrical component modules

is more likely. Less surface area for the car to ride on means greater potential

tether damage in the event of elevator drive failure. Total tether failure

is much more likely, and if the falling elevator car is inside the tether

matrix, much damage to other components is likely. It is much more likely

for debris from this sort of elevator to be guided by the other tethers

around it so that it is dropped right THROUGH the Downstation like a bomb,

rather than being thrown away from the tether and Downstation by coriolis

forces. This by itself may limit these elevators to a very small size.

Considering the long period of construction the SE is likely to face, later

nanofiber fabrication employing mechanosynthesis (ie. nanomachine fabrication)

techniques would likely emerge while the tether is still in a relatively

early stage of development. This would at first be employed in the factory

based fabrication of laminate tapes on orbit but would later be employed

more directly for the in-situ fabrication of the tether. This third generation

technology would likely take the form of a nanolaminator climber. This would

be similar to the conventional laminator climber except that it would carry

no reels of tape. Instead, it would feature a pneumatic collar with integral

radiator fins which would fit around a section of the tether defined by the

spacing of built-in gas supply ports on the face of the tether. Filled with

a slowly circulated fluid medium, this collar would host a 'culture' of nanoassemblers

which pick up CO molecules from a gas permeable plate on the gas supply

port and plug them into the nanofiber matrix on the surface of the tether

structure, producing an extremely uniform nanofiber structure. The climber

would move in sections down the tether, applying perhaps a millimeter of

material in each section. A fleet of these nanolaminators could work in

series, continuously thickening the tether at a great rate.

A fourth generation technology would take this even further, allowing the

tether to grow its structure uniformly allong its whole surface simultaneously

while also providing its own raw material. This would take the form of a

nanomachine sheath composed of a network of self-interlocking nanostructures

which create a self-expanding corrugated sheet. Along the lower in-atmosphere

section of the tether this sheet would sport an array of fin projections

or corrugations. These are covered with a molecular collector surface which

scrubs carbon dioxide from the ambient atmosphere, cracks it into carbon

monoxide and conveys it to a CO supply line inside the tether. On the inside

of this sheath the corrugations are filled with fluid hosting nanoassemblers

which use the collected carbon monoxide to assemble nanofiber in successive

simultaneous strip sections equal to the corrugated channel width. The corrugation

also allows the sheath to function as a radiator. As each strip of material

is added, the sheath expands in radius by dividing its corrugations, exposing

unfilled sections of tether surface to the assemblers. In this way the entire

tether slowly thickens uniformly and continuously, extracting its raw material

right from the atmosphere.

Both these later generation technology approaches would favor either the

corrugated structural approach -since this leaves the whole exterior surface

of the tether free while it is used for transport internally- or the monolithic

tether approach, with some relatively minor adaptations to the fabricator

configuration needed to accommodate alternate face growth.

Downstation:

The initial downstation structure would take the form of a Pneumatically

Stabilized Platform made of concrete, as developed by Float Inc. of California.

The reason for this choice is that the PSP is a low cost, modular, and self-mobile

structure which can be mostly built on-site and affords a high degree of

stability by virtue of its ability to consume all wave energy of wavelength

shorter than the platform width. It can also exploit this energy for electric

power using turbines in the inter-cell ductwork of the platform, though on

the equator relatively little power would be produced due to the calmness

of the seas -hopefully enough for station-keeping alone. Using active station-keeping

based on electric azimuth thrusters, the PSP is more stable than any floating

oil rig and, because it functions as its own breakwater, readily provides

the downstation with the ability to support large ship mooring along its

edges. This is a critical capability, since the only way cargo and personnel

can be transferred to an oil rig platform is by crane, helicopter, or cable

shuttle.

But more important, the PSP would be incrementally and indefinitely expandable,

able to maintain and expand its structure using construction facilities

on-board. This allows for maximum exploitation of the resources the space

elevator would afford in direct proportion to its scale of transport during

its incremental expansion. As development of the tether proceeds and the

variety of on-orbit activities increases, the PSP platform could freely

expand and change in configuration to provide worker housing and downstation

industrial facilities to complement emerging orbital facilities. At a certain

scale it becomes possible for the downstation to host its own commercial

scale airstrip to support air cargo and passenger transport, to host whole

families and the secondary service industries supporting them, and even to

host aquaculture farms to provide inhabitants of both downstion and space

with fresh food. In this way a whole city could evolve around the tether

downstation in the same way cities have historically developed at logical

intermodal transportation points.

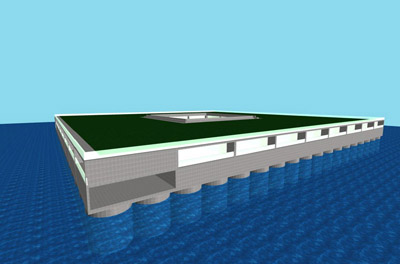

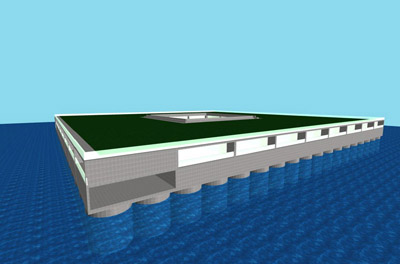

This picture, from Float Inc., shows how this structure would be composed

and built;

Let's consider the evolving architecture of this downstation structure

and the community it would host. The initial facility would be pretty simple.

Using a simple flat form, it would feature two concrete decks surrounding

a tether terminus 'well' with a simple space frame tower around it sheltered

in metal and foam composite panel or a tension membrane of Sheerfill fiberglass/teflon

fabric. The base platform deck -about 50' above sea level- is enclosed by

modular concrete bays one or more storeys high forming the upper deck and

is where most facilities would be located. Perimeter bays are enclosed in

retrofit panels, glazed or solid, and provide most of the 'habitable' space,

while the rest is equipment and storage space. A recessed portion of bay

units on one or two sides provides an open 'quayside' deck with space for

cranes, though much cargo and personnel would be transferred simply by ramp.

These are used as docks for service ships, exploiting the platform as a breakwater.

The second or 'roof' deck would host standard marine gear, telecommunications

equipment, possible wireless power transmission equipment, PV panel arrays,

and other assorted support equipment relying mostly on adapted marine shipping

container shelters. A helipad would also be located here. Basic facility

utilities would consist of PV and wave power with conventional back-up generators,

solar or electric water heating, AC provided by deep sea water, and electric

marine water generators. This initial facility could be fabricated in Sri

Lanka and would power itself out to position. All later Downstation construction

could be performed on the platform itself.

Here is a picture offering a rough idea of what this might look like;

[this is actually one of a series of designs I have worked on for a near-shore

marine condominium serving as a seed for a marine colony. This structure

would be similar in basic composition but would use larger scale PSP cells]

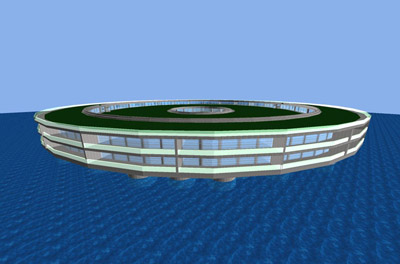

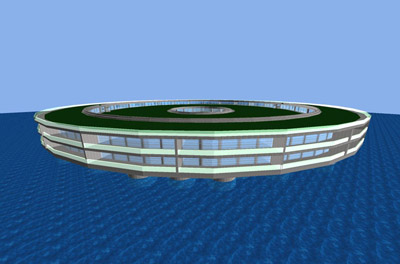

As the facility expands it would assume a more radial structure with a

larger number of decks formed of higher storey bays surrounding a deeper

well, perhaps taking a form similar to this;

At this stage the facility would begin hosting permanent staff, individual

bays on the perimeter providing apartment space and certain decks becoming

dedicated to community services like medical, recreation, and shopping.

The chief business role of the SE venture is leased facilities with leased

space on orbit complimented by corresponding support facilities on the Downstation.

In this way the Downstation would grow into a large permanent community

hosting the workers of these leased facilities and of the community services

that support them.

At a certain scale a community PRT (personal rapid transit system) running

within the deeper interior portions of the structure would be added. This

transportation system functions as a kind of elevator traveling horizontally

and vertically and using different function cabs for different jobs, some

to move people, others to move cargo up to the size of a marine shipping

container. This system would evolve from a marine container conveyor system

used inside the early structure for managing container storage and for moving

payloads and equipment to the tether terminus well. This PRT system would

also function as a PPT (personal packet transport system) using a robotic

cab to collect and convey smaller meter-sized containers door-to-door. It

would be like having a dumb-waiter than can go door-to-door throughout the

facility and would see significant use in integrating industrial systems

located in different points in the Downstation. The PRT/PPT would eventually

be integrated with the full scale space elevator car system allowing for

tight integration between on-orbit factory facilities and factories on the

Downstation. It would also have the benefit of giving Downstation residents

door-to-door transportation to space.

[PRT system with alternate supported/suspended drive and mult-size multi-function

cabs. circa late 1960s]

As it grows in area the Downstation would also climb upward around the

tether well, absorbing the earlier tether support tower enclosure, and assume

a concentrically terraced form. While open deck space near the center would

still be dedicated chiefly to the SE systems use, the lower outer areas would

tend to be dedicated to diversified industrial uses and intermediate terraces

would increasingly be given over to the use of public gardens and cold-bed

farming. This would give residences in each terrace-perimeter a more suburban

aspect, the emerging megastructure assuming the overall aspect of a mountain

sloping upward to meet the SE tether. The perimeter of this structure would

feature small round bays for small boats and recreation, large pie-segment

ports for commercial shipping, and clusters of pens for aquaculture exploiting

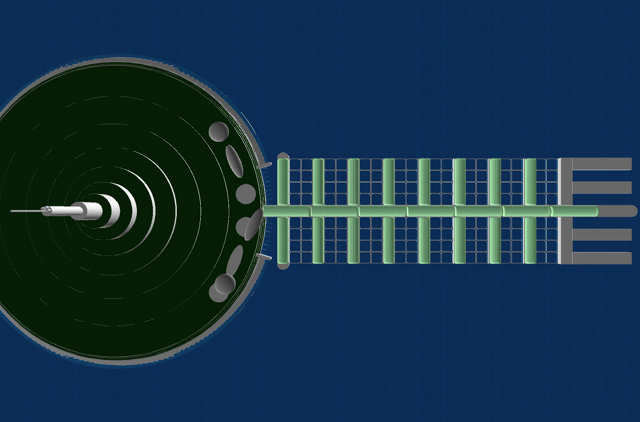

the deep-sea discharge from the downstation's deep sea water AC system.

[note: those aren't flying saucers. They're lenticular airships]

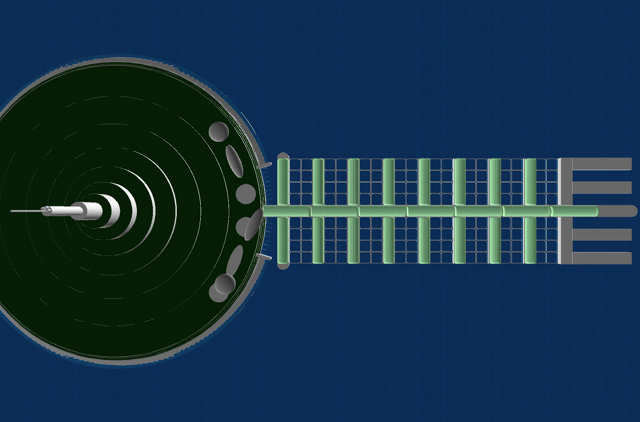

A satellite platform located some distance away -cheifly for noise abatement

reasons- would function as a commercial airstrip. Using its massive flight

decks as gigantic thermal collectors, the airstrips could double as a solar

dynamic power plant, adding to the potential power output of the facility.

Below-deck space would serve as airport facilities and a vast air cargo

terminal. It may look similar to this floating airport design from Float

Inc.;

This airstrip facility could evolve from what was initially a hybrid airship/rocket

or conventional rocket launch facility built to provide a base of vehicle

assembly and launch nearby the Downstation facility. Such a facility would

be similar to the initial Downstation structure but instead of evolving

to a radial form it would remain square, eventually sprouting airstrips

from two opposing sides. As a launch facility it would use either a vast

tension structure hangar covering its area or it would feature a large NASA

VAB-like tension structure which rides on tracks to enclose a self-mobile

floating launch pad when docked to the platform, allowing a large rocket

to be assembled on the launch pad which then moves whole to launch position.

Such a local launch facility is not strictly necessary for the initial tether

deployment but could be justified in the context of its planned evolution

to an airport when the SE obsolesces rockets in its construction plan.

Operational Scenarios:

Pre-deployment scenario:

The SE program begins with the development and testing of its initial tether

systems components. This would also be relied on for generating the media

attention required to attract investment in the initial tether deployment.

Several technology demonstrations would be key to drawing attention to the

project;

Telerobotics demonstrators: Since the small scale of the initial tether

limits most initial on-orbit activities to what can be done by telerobits,

it fall to the SE venture to demonstrate the viability of telerobotics technology

for this. This would involve the prototyping and demonstration of several

types of telerobot systems; climbers, climber laminators, on-orbit service

robots, and self-contained robot lab modules. These systems don't need to

be put in space to demonstrate their use. They simply need to demonstrate

their remotely controlled operation at a convincingly long distance and

give potential clients a feel for how operations on the Upstation would

be conducted -and inspiration for their own project ideas. The systems would,

however, be later demonstrated on the aerostat demonstrator noted below.

Hybrid airship assisted launch demonstrator: Balloon assisted sub-orbital

launches have already been well demonstrated but in a vertical vehicle orientation

with conventional sounding rockets. This project would demonstrate an initial

horizontal aligned guided dirigible assisted launch to LEO of an open space

frame payload. Smaller in scale than the full scale tether carrier system,

it would be based on the same modular components for the dirigible and tether

carrier structure, the truss using conventional rigid struts, the dirigible

using pneumatic struts. Recovery of the dirigible hull would allow its components

to be re-used in the later larger launch system. The demonstration truss

payload would function as a chassis for an academic science package or some

simple communications satellite or it could be simply sacrificed after successful

launch.

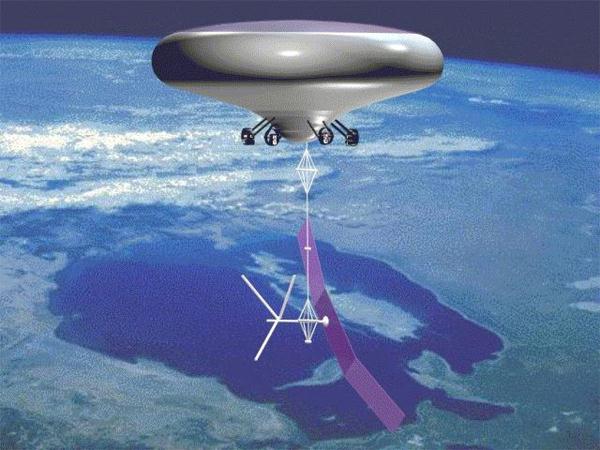

Dirigible aerostat tether demonstrator platform: This project uses essentially

the same dirigible hull system used in the hybrid launch system as the basis

of a stratospheric aerostat which supports a full-scale prototype of the

tether carrier truss. Flexcells on the dirigible hull provide power to stationkeeping

systems based on plasma thrusters, as used in telecom aerostats. This functional

mock-up tether carrier carries a short length of the same type of tether

planned for orbital deployment as well as the prototype for the 'down' terminus

instrument capsule. It would be used to test and demonstrate tether deployment,

capture, and anchoring. It would also be used as a test-bed for tether climbers,

Upstation telerobots, and power/communications systems. Development cost

recovery for this demonstrator would be achieved by its conversion into a

telecommunications aerostat which would be used to provide wireless broadband

services, as well as hosting atmospheric research systems. This itself is

potentially extremely lucrative and could be exploited as a bootstrapping

venture to finance the rest of the initial tether deployment program. This

would establish the SE venture as a revenue generating venture even BEFORE

the SE itself is deployed. A very powerful credibility booster.

[LTAS telecom aerostat platform]

Downstation platform demonstrator: This would, essentially, be the ACTUAL

initial Downstation structure. It would be built to provide the SE venture

with a tangible showcase facility featuring equipment mock-ups and could

serve as functional downstation and launch facility for the aerostat demonstrator

and hybrid rocket demonstrator. However, it would also serve very well as

a fully mobile corporate HQ, workshop, and lab facility for the SE venture

and would retain its value by being potentially resalable for off-shore

residential, industrial, or research applications. It is a mobile piece

of real estate and could be located in and later moved (move itself!) to

just about anywhere in the world. It can also recover its development cost

through the aerostat demonstrator's re-use as a telecom platform, since

it would function as its telecom downstation, and by leasing space for marine

and meteorological research facilities.

Initial deployment scenario:

Deployment begins with the launch of the initial tether carrier truss package,

either by conventional or hybrid rocket. Upon reaching GEO, the truss package

would align itself vertically, deploy its solar panels and communications

systems, and begin its uncoiling of tether from both ends. The steerable

'down' module should eliminate the problem of finding and recovering the

end of the tether as it is lowered since it would be in constant communication

with the launch control center and could be 'flown' by remote control toward

the mid-ocean Downstation.

Capture would be performed by lofting an intercept cable on moored balloons

several miles apart, similar to the capture cables deployed in the old early

20th century air mail system. This might require some protective sheathing

of the lower end of the tether to reduce damage from cable friction. The

capture cable would also double as the grounding strap for the tether. Weather

should be a minimal problem for this process because the equator is subject

to little weather, hence its maritime reputation as 'the doldrums'.

Upon capture, the tether would be towed by boat to the Downstation platform

and installed in its anchor receptical, held in place by magnets or roller-bearing

clamps with a motion compensating slack spool rig or perhaps a system of

attached dynamic ballast tanks below the water line. First order of business

after the initial tether deployment is using climbers equipped with sensing

equipment to analyze the tether integrity and test the performance of the

climbers in all conditions along the tether length. Then tether expansion

begins, alternating with payload transfers to the Upstation. It is likely

that the SE venture would go to deployment with a fairly full schedule of

Upstation and Downstation lease space clients, though these initial clients

will not be for permanent facilities due to the small scale of initial Upstation

facilities. On-orbit launch service clients would tend to come much later,

as the payload capacity of the climbers grows to allow more useful vehicle

packages.

Initial operational scenario:

Key to making this whole SE vision work is continuous revenue generation

from the tether in all stages of its construction. It MUST be able to turn

a profit from the moment the initial small tether is deployed, if not before.

It is likely that upon deployment many potential clients will line up seeking

space at the Upstation for different projects along with corresponding Downstation

support space. And, of course, there will be many people wanting to launch

satellites and other vehicles from the Upstation and higher points on the

tether. But since human habitation on-orbit and on-tether would be unlikely

for some time due to the small unit payload capacity of the rudimentary

tether(s), activities in space would be limited to what can be implemented

with small systems via telerobotics -still a very significant amount and

diversity of activity but limited in scale. Thus I see the initial operational

model for the SE being essentially the same as that of the MUOL, as noted

earlier in the Upstation design section, with that addition of space transport.

Being limited to a relatively small climber payload capacity, the small

module scale of the MUOL makes perfect sense.

The basic premise here is that the Upstation structure presents a kind

of 'real estate' which is organized into lease space units according to

its modular geometry and the form factor of unit modules which plug into

it. The SE venture's job is akin to that of the management of a large commercial

office building; building and maintaining unit space which lease clients

use as they wish within the practical limits of safety and available infrastructure

services. The vertical orientation of the initial truss relative to the Earth

is less well suited to this than the horizontal planar space frame of the

MUOL because many applications -particularly telecommunications ones- require

an unobstructed terrestrial view. Telecommunications being the most likely

initial adopters of space on the Upstation, its first order of business would

be to construct a perpendicular plane space frame around the core truss -as

described previously- in order to mount this type of equipment. This would

take the form of first a simple boom which is widened until it completely

surrounds the core truss.

After telecommunications, the next area of in-space business would be industrial

research, the structure providing plug-in space for automated modular lab

units. These would take the form of temporary labs, removed whole after

completion of their work and either discarded or returned to Earth, or permanent

labs, which are periodically serviced with their own plug-in modules in

order to restock them with supplies or to remove process samples. This phase

of use is critical to the future of the SE and the future of space development

in general since space will only see sustainable investment when a robust

assortment of products valuable on Earth can/must be manufactured in space.

Like any space program, the SE faces the challenge of inventing reasons

for its existence. This is why orbital industrial research is critical.

(why that hasn't always been obvious to people in NASA is beyond me. There

is no more important 'mission' for the future of the space program than

in-space industrial research)

Logically enough, the next development phase would be the implementation

of on-orbit factories, some of which would be operated by the SE venture

itself in order to fabricate tether material on-orbit for its expansion.

We can't precisely predict what products are likely to emerge out of the

orbital industrial research but likely areas will be in photonics, microelectronics,

drug synthesis, bio-engineering, and nanofabrication exploiting the vacuum

and microgravity. First generation factory modules will be similar to first

generation lab modules, designed as small fully self contained packages which

are brought to the Upstation whole and brought back when they are depleted

of materials. Second generation systems would use plug-in casettes for input

and output. Later units will split into separate plant and transport modules,

then into multi-module production lines where different workstation modules

are linked together through module access ports. The likely architecture

of these factory systems would be simple, building upon the architecture

of lab modules. Process hardware consisting of plug-in modules are arranged

radially around a central open space, each plugging into a radial backplane

like computer boards and accessed by a set of simple telerobots operating

on a track shaft running through the module center. A telescoping extension

of the track shaft allows the robots access these add-on compartments while

side-to-side ports allow robots in one module to hand off items to those

in adjacent modules. Following this design strategy, factories of most any

scale would be possible, with the bulk of the products limited by the size

of the unit modules.

Since the first generation of lease clients would be running telecom systems

and labs, the companion Downstation facilities they would lease space for

would be primarily control centers and small service workshops. This would

be further supplemented by non-space facilities in the form of marine and

meteorological research facilities. So right away we could see a sizeable

contingent at the Downstation, even though it would be a relatively compact

facility. However, this would increase in proportion to the payload capacity

of the climbers/elevators and the transition to on-orbit manufacture, becoming

comparable with any conventional light industrial facilities by the time

the first full scale elevator system is installed. Eventually the Downstation

would be hosting all the product processing that can be done on the ground

around materials or subcomponents made in space, outputting a finished packaged

product for export.

As for the SE's use as a launch platform, this capability would tend to

be initially limited to small very small self-contained spacecraft which use

ion/plasma propulsion and/or solar sails and tether spools for propulsion.

In essence, microsatellites. Launch would be based on climber transport

to the Upstation and then release via the Upstation's own robot arms or

by a robot on a climber which travels to points above GEO on the tether

length, exploiting the centripetal force to send vehicles to other points

on GEO and to escape trajectories. However, by employing the same component

architecture used by the Upstation structure itself it becomes possible

to overcome the payload limits of the early thin tether by assembling modular

spacecraft on-orbit. Vehicles of any size would be possible, including manned

spacecraft based on transhab habitat components -this even before the tether

itself can support human passenger traffic. This offers a whole new service

area for the SE venture; manufacture of spacecraft on demand from modular

components. This would require both dedicated assembly 'creche' space on

the Upstation and manufacturing facilities on the Downstation. The most likely

initial uses for this capability would be the construction of very large

telecommunications platforms intended for other GEO locations, followed

by solar power satellites, prototype solar sail spacecraft, as well as interplanetary

research vehicles.

Initial operations at the Downstation would rely heavily on Sri Lanka or

the Maldives as a point of relay, for supplies, workers, and communications.

All equipment for use in space will be manufactured elsewhere -primarily

in North America, Europe, Russia, and Japan- and sent to the site, through

air ports and ports in Sri Lanka or the Maldives. Local facilities could

be robust, but most initial workers will still work in shifts akin to that

of oil rig operations and that means coping with a high transportation overhead

and a high salary because of the inconvenience these works must deal with.

This points out a key issue.

The most critical logistical issue for the SE venture is, ironically, transportation

to the Downstation from and to the rest of the globe. The Downstation is

still going to be at a relatively remote location; 400-600 miles from either

the Maldives or Sri Lanka. This is beyond the typical range for helicopters,

which are not cost effective in any case, and while the structure itself

could readily support container ship service, the SE venture will not be

big enough to be put on container ship routes for a while. It will also be

too small to host an airstrip large enough for commercial air liners. An

airstrip capable of supporting commercial airliners would be about 2700-3000

meters by 100 meters and would cost in the area of $2.5-$3 billion dollars

based on PSP construction. (that's conservative. For a mid-ocean airstrip

supporting aircraft on par with the 747 airlines could demand a length of

3500m and twice the width. An Atonov heavy cargo aircraft requires a basic

3500m runway) That would likely have to wait for a while, unless it was already

built as part of a pre-deployment marine launch facility which was paying

for it through operation as a commercial launch facility.

This presents a real problem because current transportation technology

offers no low cost, intermediate scale, long range transportation options.

Thus the SE venture is initially forced to relay from these two nearest coasts

and must bear the cost of its own relay transportation. There are three classes

of vehicles readily available that offer the most likely choice for this;

First is the oil industry type 150-300 foot PSVs (platform supply vessel),

mini-supply vessels, or FSVs (fast supply vessels) capable of carrying several

shipping containers, palletized cargo, and 50-70 passengers. All these vessels

are similar in form, with slight variations in engine power, flat deck area,

and interior passenger accommodations. But they only manage about 25-30

knots, have very limited range, and cost in the area of several million

dollars each, new. 1000 miles may be their range limit.

Next is intermediate sized RoRo (roll on roll off) container/cargo ships.

Typically used for secondary shipping and ferry service for island communities,

these are 250-400 feet in length and can be purchased used for between $2-10

million dollars -$10-15 million new- have a capacity of about 100-150 20'

containers, and manage about 15 knots. This is a pretty good class of vessel

for the Downstation's needs when coupled with the side-docking capability

of the PSP because these vessels are multi-function, offering container,

vehicle, and pallet handling with Roll-On-Roll-Off handling via on-board

ramp systems. They may also have much longer range than PSVs. But their

very slow speed is a bit of a problem for use in longer range transport.

They would put the Downstation at around 40 hours from the Maldives or Sri

Lanka. There is a possibility that lease service of these intermediate class

vessels is possible from Sri Lanka as it is likely to be hosting that service

for the benefit of the Maldives. If this can be determined, it would make

the initial transportation logistics more streightforward but may not be

comfortable for routine passenger transport. If the vessels were owned,

this could be readily overcome by converting a certain portion of container

space to passenger cabins using adapted shipping containers.

The next most likely option is the so called 'fast ferry' class of vessels.

These are typified by multi-hull vessels in the 100'-125' range used mostly

for inter-island, large bay area, and intercoastal transport. They offer

relatively high speeds in the area of 40 knots but with high fuel consumption

and cost in the area of $20-40 million dollars new, around $15 million used.

This class of vehicles would put the Maldives and Sri Lanka at 10-15 hours

away. SWATH (small water area twin hull) offer the best performance and fuel

efficiency with the most stable ride but remain rare and expensive. Designed

mostly for passenger service, fast ferries offer high passenger capacities

up to a few hundred people but with accommodations designed for short range

ferry service and fuel tanking limited to short ranges. However, their catamaran

hulls and clear-span superstructures make them easy to adapt, thus allowing

ready refitting or customizing to support long range multi-function use.

Likely configurations would offer passenger capacities in the area of 30-50

passengers and palletized cargo handling but no container handling, due to

the typically light aluminum deck structure. This adaptation would add about

a third to the vessel cost. These might be a better choice as a specialized

passenger vehicle rather than a mixed use vehicle. New marine capable RoRo

fast-ships with mixed-use intermediate cargo capacity are starting to appear

but remain too new to be found used.

[recently developed fast-ship RoRo mixed use cargo and passenger vessel

operating out of Australia. 41knot cruising speed]

Long term, the SE venture needs to free itself from relying solely on Sri

Lanka and the Maldives as waypoints in order to support consistent growth,

possibly sooner than its scale will justify more conventional transport

options. So more unconventional transport may need to be explored.

Sea planes are no solution because ones large enough to land and take off

in the open sea no longer exist. However, there is one similar vehicle which

may offer this capability; the Orlyonok Ekranoplane, made by Volga Shipyards.

Marketed as a kind of fast ferry, this is the closest thing we have today

to a jet airliner that can land on the open sea, though technically it's

a surface effect vehicle that never gets above 50' altitude. The Ekranoplane

is a very efficient vehicle, offering high speeds but at less fuel consumption

per flight hour than conventional aircraft of comperable size and speed.

It uses three engines; two nose mounted jet engines and one tail mounted

turboprop. In flight only the turboprop is used, the nose jets only providing

take-off assistance. It costs about $40 million, has an operating cost of

about $5000 per flight hour, has a capacity of 250 passengers or 180 metric

tons of cargo, has a cruising speed of 430kph, can land and take off in 2

meter (category 5) seas, and would have the range to reach everything from

East Africa to Malaysia in a single hop. But it's still a pretty expensive

vehicle. One version of this vehicle was designed for nose-seperation loading

(it's original role was as a very high speed long range landing craft) which

would be fine for palletized cargo but it is not clear if it can accommodate

marine containers. Air cargo containers should be readily supported.

Using the technology employed in a hybrid launch system, it is possible

the SE venture could solve its transportation dilemma by adapting the launch

vehicle hull technology to use as a general transport dirigible airship.

Such vehicles would be similar to or the same as the vehicles proposed by

the LTAS corporation [ http://www.lvcm.com/walden/

] using hybrid propulsion based on a combination of flex-cell PV sourced

solar power and a compact turbogenerator or fuel cell. Traveling on fuel,

they would have a range equivalent to the Orlyonok but a cruising speed of

about 150mph. On solar power alone these vehicles would have an unlimited

range at a cruising speed of about 60mph. They could operate in either mode

on demand. They offer the lowest operating cost of all forms of air -or sea-

transportation, regardless of which operating mode is used. The old technology

Hindenburg could travel from NY to LA on less fuel than a 747 consumes taxing

on the runway. Using the same materials as the SE tether itself, this performance

could be increased much further by virtue of a much lighter, stronger, and

thinner shaped hull system. Hangar facilities are unecessary for lenticular

hull airships because their cross-wind susceptibility is much lower and, relying

on the control technology used for the hybrid launch system, vehicles can

be simply parked in the stratosphere when not in use. Such vehicles have a

distinct advantage in that the SE venture could manufacture them itself while

their VTOL capability makes it easy to service the Downstation and reach

deep inland areas. It is both practical transport and a valuable product.

This makes synergistic use of the fabrication capability the venture must

develop for a hybrid launch vehicle, aerostat demonstrator, and for climbers

and elevators.

[three sizes of lenticular airship. Pictures from LTAS]

Much of this transport problem could be alleviated by reducing the need

to use workers in shifts as with oil rig operations, instead equipping the

Downstation to allow them and their families to live comfortably on the Downstation

itself for indefinite periods. The greater the self-sufficiency of the Downstation,

the more community-like its aspect, the lower the rate of worker rotation,

the lower the dependency on Sri Lanka and the Maldives for worker accommodations,

the less critical high speed passenger transport becomes, and hence the

lower the operational transport overhead. The more permanent residents the

Downstation can host the more net transport volume for the complex, the

sooner it can get container ship line recognition and the sooner it can

cover the costs of a commercial airstrip. So the logistics of Downstation

operation favor its evolution into a full-blown city or marine colony.

Later operational scenario:

As we've already established, revenue streams for the SE venture -that

is to say the sources of income- would be both ground and orbit based with

the essential role of the SE venture being that of a leased space and space

transport service provider which provides space -on-orbit, on-tether, and

on the Downstation- for different industrial and commercial activities and,

of course, the transportation and communications linking them. It's important

to recognize that the Downstation structure -as the closest point of space

access- is just as valuable a commercial asset as anything in space -in

fact, potentially more so because the volume of Downstation space demand

will grow faster than the Upstation space demand.

The reason for this is that, even though the SE itself drastically reduces

transportation costs to space, doing things in space will still be more

expensive than doing things on the ground due to the rigors of the environment

facilities must deal with there. Even if it cost you nothing to travel to

and from Antarctica, a factory built there would always be much more expensive

than the same sized facility in California because it must tolerate a vastly

more harsh environment and so is inherently more expensive to build and

operate. So in the event of a robust Upstation industrial facility, it's

matching Downstation facilities may be many times larger because companies

will only put what absolutely must be put in space and leave the rest on

the ground nearest the point of access to space. Why put all this factory

space on the Downstation rather than in Sri Lanka? Initially, much of it

may be put there. But the site of the Downstation is still remote enough

that the transportation overhead between Sri Lanka -or from there to anywhere

else on the globe for that matter- and the Downstation would be high and

result in much production delay. This would be true even after the Downstation

can host container ships and full size airliners. So in the long run economics

favors complete production to a finished packaged product at the Downstation

for direct transport to their markets aorund the globe.

Here then is the driving force that turns the Downstation into a large

self-supporting community -a full-blown marine colony. All this activity

would require a fairly large worker base but cycling them between the Downstation

and its nearest neighbors is more expensive than having them live continuously

on the Downstation. It also presents a certain hardship to workers to be

seperated from family for extended periods -one reason for their higher salaries.

Thus it becomes more economical for the Downstation itself to host facilities

not only for workers but their families as well, and thus you have the makings

of a complete community as community support services -shops, restaurants,

schools, clinics, recreation, personal transportation, personal financial

services, agriculture- follow on the heels of these families. Initially all

food and supplies would be imported to the Downstation but, again, this is

more expensive then producing them locally if possible. Using deep sea water

for AC and industrial cooling, the Downstation has a very useful agricultural

resource. This artificial upwelling would provide the basis of polyspecies

mariculture using simple floating pens and frames attached to the perimeter

of the Downstation platform and algaeculture solar frames on the roofs/terraces.

The cold water also enables the use of cold-bed farming which allows the

creation of compact farms supporting temperate climate crops. Algaeculture

and mariculture would provide a source of nutrients for hydroponics, supporting

this rooftop farming. Carry this out to its logical conclusion and you get

the makings of a complete self-supporting community. This is why it's so

important for the Downstation structure to be so freely expandable.

While leased space and space transport would be the SE venture's primary

areas of business, a number of other industries would be critical enough

to the SE development project itself that the venture would most likely need

to implement them. One is telecommunications, primarily between the downstation

and the upstations but also between points throughout the wireless telecom

'footprint' of the GEO upstation. With submarine cable link to Sri Lanka

and India, this becomes a powerful source of revenue in and of itself, the

SE capable of providing freely expandable wireless telecom services (phone,

TV, Internet) across much of Asia and Africa.

Next is electric power. The tether itself is a potential source of power

as an electrodynamic generator. In addition, the GEO upstation would serve

as a good solar power satellite platform and a nexus for multiple SPSs,

communicating their power to the upstation by laser or microwave link. There

are many ways for the tether to communicate power to the downstation. If

it's designed as an electrodynamic system, it is already delivering its power

to the surface and the downstation need only 'plug in' to the tether. However,

the great length of the tether may present so much net resistance that,

being a DC system, only by equipping it with a superconducting cable could

its full power potential be tapped. Otherwise, it could serve as a simple

coaxial cable for power sent via high frequency modulation or in the form

of microwaves to the surface. However, the long distance could still mean