Optomechanical bonding or mounting with adhesives has demanding requirements which are more severe than most other bonding applications. Stress must be minimized to prevent optical distortion and must be considered over the entire operating temperature. No failures are desired along the bondline and bonded components must remain precisely located over their entire lifetime.

Ultraviolet Curing (UV) adhesives can offer advantages for fastening or mounting of optics if the mechanical design is configured to take advantage of the handling characteristics of the adhesive. Use of these materials simplifies any process that requires critical alignment or exact positioning.

This paper describes some of the

considerations which must be taken in order to chose the best UV adhesive

and how to control them for maximum performance in a system.

DESIGN CONSIDERATIONS

Type and size of optics

In general, only small, low mass,

optics up to about 2" or 3" diameter are suitable for mounting with UV

adhesives. This is due to the limitations in acceptable bondline thickness

which can be easily cured without creating an excessive amount of shrinkage

and inherent stress. Common bondline thickness can range from 0.010" to

0.250". Typical optical components which are good candidates for UV adhesive

mounting are lenses, prisms, filters, mirrors, as well as fiber optics.

Essentially any bondable substrate

can be designed into the system. Best choices are glass ,metal, glass filled

plastics, and the various engineering plastics now available. Undesirable

plastic substrates are unfilled nylon, delrin®, teflon®, polyethylene

and polypropylene.

Physical properties of adhesive

With the wide variety of UV adhesive types available today, it is important to consider the physical properties desired for optimum optomechanical performance. Among the many properties, the most important are shrinkage, adhesion, modulus of elasticity, and elongation.

These physical properties are all interrelated. It is not possible to look at one property alone to determine suitability. It often will be a trade off of decreasing one property to increase another more desirable property. In the end, a balance of properties is typically needed.

To minimize stress and provide long term stability, the lowest possible shrinkage is desirable. It is impossible to completely eliminate shrinkage. Fortunately, stress can also be minimized by the cure configuration discussed later in this paper.

Adhesion, modulus of elasticity, and elongation must have the proper balance for optimum performance. Good adhesion is necessary to stand up to shock, temperature cycling, and differential expansion, but a more resilient product, ie. lower modulus with higher elongation may be more desirable to withstand these same conditions. A lower modulus adhesive can provide a certain amount of stress relief when the material stretches to eliminate the stressed condition.

Glass transition temperature (Tg)

is sometimes considered to be a critical property to indicate maximum temperature

range. This is the temperature where the physical properties change from

'glassy' state to a 'rubbery' state. Tg can be critical for rigid materials,

because the sudden change in the physical properties can affect performance.

It is much less critical for resilient materials, which are already flexible

and do not change as drastically.

Cure considerations

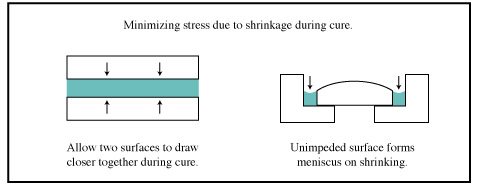

An understanding of how shrinkage occurs is important in order to minimize stress. Because UV light enters at the surface and penetrates into the adhesive, the curing and shrinkage occur from that surface down. If substrates are allowed to move closer together as shrinkage occurs, stress can be minimized. Alternately, in mounting applications, if a wide bead of adhesive is used around the edge of the optics, the adhesive can shrink from the surface down which helps to minimize stress.

Another factor is the speed of cure (i.e. light intensity). Higher intensity UV light provides a faster, more penetrating, depth cure but can lead to more stress. Lower intensity light allows for slower cure. This more gradual cure and shrinkage from surface down appears to minimize stress.

UV curing is so quick and simple, it is easy to think of the light as a magic wand which can be waved over the component and everything will magically cure. It must be understood that UV light behaves identically to visible light. It will follow the available optical path but will not bend around corners and will not appreciably scatter sideways into small gaps beside the optics. There are products which have a 'shadow cure' where exposed adhesive can propagate the cure sideways to a small degree and other products that can be heat cured to complete the cure in areas unexposed to light, but care must be taken to check for the stresses after cure.

The key to UV curing for optics is uniformity of illumination. Be sure to have even intensity, with no shadows over the bondline. A gradual change is acceptable but any sudden changes lead to internal stress in the adhesive itself. This will always cause instability over long term.

It is important to be aware of light

source position. It must be located where it will see the adhesive. A simple

check is the 'eyeball' test. If the adhesive bondline can be seen by the

eye, the UV light source can see it from that same location, too. If the

bondline cannot be seen with the eye, UV curing will be a problem.

Testing

Theoretical calculations can only

supply an indication of an adhesives performance. The greatest assurance

is provided by testing it in the actual application. After an initial screening

for adhesion and testing for stress or optical distortion, running samples

through environmental testing is the best way to evaluate the long term

performance of an adhesive. Comparative tests among different materials

with temperature cycling, shock, and accelerated heat aging will quickly

indicate any changes in the adhesive bondline and determine the acceptable

products.

TYPICAL APPLICATIONS

There are a multitude of techniques used to mount optical components with adhesives. Here are a variety of illustrations for mounting lens, filters, windows, prism and mirrors. Note how the configurations allow for efficient UV cure.

CONCLUSION

UV adhesives provide an efficient method of providing fast precision alignment or exact positioning of optical components. They are suitable for use in optomechanical designs when ease of assembly, reduction of weight and long performance are desired. To take advantage of UV curing adhesives, proper understanding of the capabilities and limitations are needed.

Choosing the best adhesive for mounting of optics requires analyzing the key physical properties such as adhesion to substrates, shrinkage, modulus and elongation. The adhesive must have the correct balance of elasticity to take differential expansion yet not allow any sag or shifting.

Care must be taken to provide optimum curing of UV adhesives. The mounting configuration must be designed to maximize uniformity of UV exposure and minimize stress during cure.

Delrin and Teflon are registered

trademarks of Dupont de Nemour.