What is a HYBRID? In my case, a HYBRID refers to any car that does not have the original motor it came with. Instead, it has a motor from another car. Here, a hybrid refers to late model Hondas, namely the 1989 Civic Si with engines from Acuras and Hondas, like the Acura Integra.

The SOHC VTEC motor (D16Z6) from a 5G Civic(1992-1995) Si (EX in the U.S) and D16Y8 will bolt to the 4G transmission found on 89-91 CRX/civic Si and DX allowing it to drop into the car with no cutting or welding. That's why this swap is so easy. All of the 4G stock mounts are utilized, dramatically simplifying the install.

The 4G Si intake/fuel system can be bolted to the VTEC block, so that the 4G ECU is retained and there is very little wiring changes. Only the VTEC controller will have to be bought.

Below you shall find all the information needed to complete the swap. Please don't email me with questions, I've done this back in 97 and I don't have this set up any more.

Legalities

NEEDED PARTS FOR THE SWAP

CLUTCH

It is better to use the 91 or 92-95 clutch (both are same diameter) because it has bigger disc giving you more friction material surface. Consequently, it'll take more abuse before it starts slipping. If you use 92-95 flywheel, you have to use the 92-95 clutch disc and pressure plate. Same goes for the 89-91 flywheel; you have to use the same clutch kit. Moreover, 92-95 flywheel is slightly lighter than 89-91 by about a pound or two. In any scenario though, it's IMPORTANT to use the 89-91 throughout bearing in both cases.

ECU

There are few options here. You could use the 92-95 Si ECU (P28), or JDM PR3/PW0 or the original 89-91 Si (PM6) unit. For the ease of the swap, use the PM6 ECU with the 92-95 fuel pressure regulator and with VTEC RPM switch activation.

In my opinion, the best option is JDM PW0/PR3 ECU. I found PR3 to feel stronger. There is a GREAT difference in performance between PM6 and JDM PW0.

INTAKE MANIFOLD

The simplest route is reusing the stock 4G intake. That intake has smaller runners and shape compared to Z6 or Y8. Should you choose to go with the mini me ITR Y8 intake manifold, here are some facts.

Get the Y8 intake if you can first. Z6 is your 2nd choice. 5G and 6 G TBs have the MAP sensor mounted on them. These TB-mounted MAP sensors work fine with 4G ECU. It's the same exact type of signal. The 5G and 6G TB TPS also work fine with 4G ECUs. The Y8's and Z6's throttle cable bracket is a perfect fit for the 4G throttle cable.

If you can get hold of a 92+ Civic EVAP solenoid, you can get rid of that firewall-mount MAP assembly altogether. You need the plug for that solenoid though, as 4G uses a different plug. You only have to extend the wiring a little and get a longer vacuum hose for the EVAP.

6G intakes have FPR located on the passenger side. You'll have to run a longer hose to the return line.

6G's don't have the air temp sensor screwed into the intake manifold. Relocate your present sensor somewhere on the airbox or the intake tube.

Don't reuse the big-hose EVAP solenoid that came with the Y8 (it's bolted on the fuel rail). Unbolt it and plug up the vacuum port.

One sensor (FIV) found in 4G si is not found on Z6 nor Y8. You don't have to use it. It will NOT throw a code with PM6, PW0 or PR3.

There are extra bolt holes on the fuel rail when doing the conversion. It's at the right spot to put a cushion clamp to hold the clutch cable.

You don't have to use the intake support bracket to the engine block.

ITR Throttle body will bolt onto both, D16Z6 and D16Y8 Intake Manifolds, but will NOT to 4G D16A6.

Going with the original Z6 intake manifold, you'll have to do very few changes to adapt it to the 89-91 wiring harness. The fuel pressure regulator is mounted in such a way that the plastic injector wire cover has to be trimmed a little. 4 G injector fit no problem the Z6 manifold. You can go with the 5G fuel line (fuel filter to the rail) or the 4G. Both mount onto the 4G fuel filter. 5G EACV works well with 4G Electronic for PM6 and JDM PW0 or PR3. Same goes for MAP sensor. Just extend MAP sensor and Air Temp Sensor wires.

INJECTORS/FUEL DELIVERY

Use the stock from 89-91 si. From the reports of some, the 95 injectors will work with the 88-91 ECU but I don't really recommend it. Why would you try to substitute the saturated type injectors with peak hold units into a system designed for peak hold units???

There's really no difference compared to 88-91 injectors as far as the fuel delivery capacity (lbs/hr or cc) of the injectors. THe 88-95 si injectors are rated at 275cc/min. Even the integra LS injectors from 90-93 are the same size injectors! One of the difference is that the 88-91 civics/crx and 90-93LS are peak/hold type injectors while the 92-95 civics and 94-99 integras are saturated injectors. Moreover, the difference also lies in the coil resistance of each injector. The 88-91 Si injectors have pretty low resistances and that's why you should use the 88-91 resistor box, which is also why you shouldn't mis-match 88-91 and 92-95 ECU's. Finally, putting it all together, the difference in fuel delivery is that as already mentioned, 89-91 pressure regulator is rated at 36-37 psi while the 92-95 is 41-47 psi hence that's why you want to use the 88-91 injectors with 92-95 fuel pressure regulator bolted on the 88-91 fuel rail to compensate for the extra air when the VTEC kicks-in!

Stock 4G Si fuel pump is good for upto 8 psi of boost! Remember, it's the regulator that determines the fuel pressure, not the pump.

If you really want to compesate for the sligthly smaller fuel map program which is on the PM6 ECU (89-91 Si) compared to the 92-95 Si ECU, get a B&M Commandflow, set it at 48-50 PSI.

Next, your fuel rail is good for upto 200HP at the wheels!

The 89-91 fuel return line is bigger in diameter than the 92-95. Thus to mount the 92-95 fuel pressure regulator onto the 89-91 fuel return line, all you need is an adjustable clamp. Tighten it well. Check for fuel leaks.

DISTRIBUTOR

92-95 WON'T work with 89-91 ECU. Use 89-91 si. You'll have to modify it somewhat if you're using D16Z6 block. No fancy machining needed. Just do it right and use big washers on the bolts and then get it timed to the red mark of the pulley. The distributor has 3 mounting holes: one closer to the fire wall (don't touch this one), one sort of on top and one closer to the rad. These two will have to be cut/modified. Not that much of a deal though, eh?! But, if you're swapping in the D16Y8 from a 96 on civic, your 4G distributor will bolt with 3 bolts onto the Y8 block!

VTEC

Stock setting is 4,800rpm supposedly but for performance factor, 4,000RPM seems to work just fine with PM6. The reason why that they have it set up or they recommended above 5k because of better fuel economy and emission control. Setting it at 4,000rpm for the track, you're power curve would be smoother than stock, but if you want to feel slight G's when the VTEC kicks in or to find out if your VTEC works then set it at 5,200 rpm. You'll know when it kicks in. Without the VTEC, the power starts to drop at 4,400 to 4,600 rpm. VTEC connects at the green/white wire plug. You do not need to hook up any wires to the oil pressure switch. That's only for the 92-95 ECU or JDM PW0/PR3. For daily driving, my new VTEC block runs on dope from 4600rpm on! ...till I switched over to the JDM PR3 where it's set at 4800RPM.

VTEC CONTROLLER

I used Summit Racing one, part#SUM-830449. The Summit unit doesn't require pills and it's cheaper than the MSD unit. This device provides -ve trigger (ground) at centain rpm. You'll have to convert that signal to +12V since this device ONLY provides ground when selected RPM is reached. Your Honda VTEC won't engage if you provide negative trigger to the VTEC solenoid. It has to be +12V. Consequently, you CANNOT use the RPM switch alone to activate the VTEC. You need to convert this ground to +12V. Please e-mail me for an ideal way of doing that using my custom converter. Forget about using the relay. I don't like relays because for starters, a typical coil of a relay has a DC resistance of about 82 Ohms. THis yields current of obout only 140 mA with a 12V source. (NOT MUCH). Next, it takes about 0.4 seconds or so to flip the switch. In that much time at about 4,500rpm, that throws my VTEC activation point by a lot. Moreover, this flipping action of a relay is not constant in time. It also depends on the ambient temperature. Moreover, when you do reach that desired activation point, the relay switches on and off many, many times, I'm not so sure this on and off action is too good on the vtec solenoid. (and on your ears... soo annoying) Therefore, due to the fact that moving parts are always prone to problems and the other arguments mentioned, I do not like using a relay to activate VTEC solenoid. ...and if you're are running a turbo, super charger or NOS, indicate that in your email and I'll ship the coverter FAST!

HEADERS

At first, I used stock 92-95 si headers with 92-95 A-pipe. This exhaust manifold is of a 4-2-1 design compared to the 4-1 in 89-91 si. I reused my old header gasket. Nothing wrong with the old one. It would be a good idea to go to some muffler shop and replace the 2 bolts and springs attaching catalitic converter to the A-pipe before you start any work on your hybrid. It just makes things a lot easier. You could use the 89-91 Si headers but the A-pipe will be close to the oil pan.

OXYGEN SENSOR

You'll have to use 89-91 si O2 sensor. It bolts into the 92-95 header. Use 22mm open end wrench to get it out. Don't forget to put some anti-cease compand on the O2 sensor's treads.

COOLANT SENSOR (FAN SWITCH)

If your D16Z6 is a 92, you'll have to take off your old coolant sensor(it's actually a fan switch, the main coolant sensor is located just below the distributor) from the 88-91 engine. This is located at the back of the block next to the oil filter. It is the sensor with 2 prongs. You'll have to transfer this sensor to the new block which has a bolt in place of it. Remove that bolt and insert the old fan switch.

ALTERNATOR

No rewiring with the alternator. The 92-95 is rated at 70 amps and plugs into the 89-91 harness. Get it. It's worth it! You could go with the 89-91 but there is some modifications to be done on the 89-91 mounting bracket if you don't have the 92-95 mounting bracket. The 89-91 alternator mounts onto the 92-95 bracket without any modifications. No need to upgrade your fusable links (main power fuse, which is 60A in the 89-91 wire harness)if you go with the 92-95 70A alternator.

Please note that the 92-95 alternator belt is wider than the 89-91 (4g has 3 rib belt while 5g has 4 rib). I think you can use the 92-95 crank pulley (which is smaller than the 89-91)with the 89-91 alternator; naturally the 89-91 alternator belt will have to be used in this case. Just to let you know about a little secret, the Integra LS (1999,2000) alternator is rated at 90 A and I think it will bolt in!!

CRANK PULLEY (92-95)

The best way to get the bolt off is with the air guy. If you don't have one, try this. I bought a big nut which bearly fits into the pulley but still allows a socket to go through it and onto the pulley's bolt. Next I got a big plummer's wrench which holds this big nut in place (and consequently the pulley) allowing me to loosen the carnk pulley bolt. More important is the fact that only the 92-95 crank shaft pulley in its original shape should be used in this swap. Weight reduction with balancing should NOT be done. Moreover, DO NOT get an aftermarket lightweight pulley or even use a factory 4G Si or the 2.5 lb DX pulley. It'll ruin your main bearings and crankshaft in about 10,000 miles! Consider yourself warned.

A/C

My civic came with A/C. You can bolt it onto the VTEC block. Reuse the 89-91 compressor mounting bracket. It bolts onto the D16Z6 and D16Y8 blocks.

ENGINE MOUNT

Remove the drivers side mounting bracket from the 89-91 motor and bolt that onto the 92-95. After 40K, I found the belt to rub a bit on the mount. It's a good idea to shave some of the metal off. 1/8" should do the trick.

EMISSIONS TEST

If you're in Canada (GTA), they'll do the test based on the engine you previously had. So, in my case it was D16A6. I wasn't asked any questions about the engine. They knew that the engine was from a 5G VTEC civic. FUEL ECONOMY

Just in case you're wondering, in my first month of testing my hybrid, driving 70% on the highway and 30% in the city, best I did in August of 1999 was 6.2L/100km. This was with the following setup: 20 deg BTDC, K&N drop in replacement air filter, custom cold air intake, full synthetic oil (Mobil 1 5W30), Honda OEM oil filter, tighter valve lash (0.005" intake, 0.009" exhaust on a COLD ENGINE with slight drag on the feel gauge), 92 octane fuel and a full stock exhaust!

![]() CIVIC TUNING

CIVIC TUNING

Before you do any tuning, make sure that there are no ECU problem codes stored. Take care of those before you attempt any tuning. Moreover, you want to make sure your plugs are fresh, distributor cap and wires are in good shape and your oil has been changed recently. And finally, make sure all your accessories are turned off.

IDLE RPMS

Make sure that your idle RPMs are below 600 RPM. If not, set it in the following way.

First, check that the TPS sensor reads 0.45V with TB completely closed. To get mine to read 0.45V, I had to remove the two screws (M5x0.8x15 for replacement) holding TPS on the TB and also remove the two metal housing through which those 2 screw go to get that reading. Without doing that, the most I could drop the voltage was 0.63V. Removing those metal housings gave me the necessary slack to achieve that desirable 0.45V.

This voltage is diffenrent for different ECUs. For JDM PR3/PW0 set it for 0.45V. For PM6, set it at 0.5V. I had to change it to 0.55V for one CRX as it would throw TPS sensor code if I set it at 0.5V. I guess some cars will vary, but you want to aim for 0.5V dead on.

Once you have TPS done, adjust your idle speed. With engine hot, unplug the EACV. If you're not at 500RPM, adjust the idle speed with the Air Bypass Screw. Once that's achieved reset your ECU.

If you cannot achieve to set your idle because you played with the forbidden throttle stop screw, set it by simply unscrewing it till the throttle rests against the bore. Then turn the stop screw in till it starts to move the throttle plate. Go an additional 1/2 to 3/4 turn.

If you still can't get a steady idle with the engine hot, check you FIV.

Set your ignition timing to the manufactures specifications, i.e. the middle RED timing mark (base setting). This is accomplished by having your idle speed BELOW 600 RPM and a hot engine. If you're setting it at a higher RPM, your timing can be retarded up to 10 degrees! Moreover, if you're setting the timing before the fans come on, the engine will not come to final advance until the temp is up and the fans start.

Bring your cam timing back to zero.

You want to run your engine in OPEN LOOP while tuning. If not, ECU will change the A/F mixture with the oxygen sensor.

More Coming soon!!!!!!!!!!

OPTIMUM SHIFTING POINTS WITH D16Z6 & 4G Si TRANY

1-2 Redline (7200 RPM)

2-3 Redline (7200 RPM)

3-4 6970 RPM

4-5 6340 RPM

Track testing is the final word on when to shift, just keep that in mind.

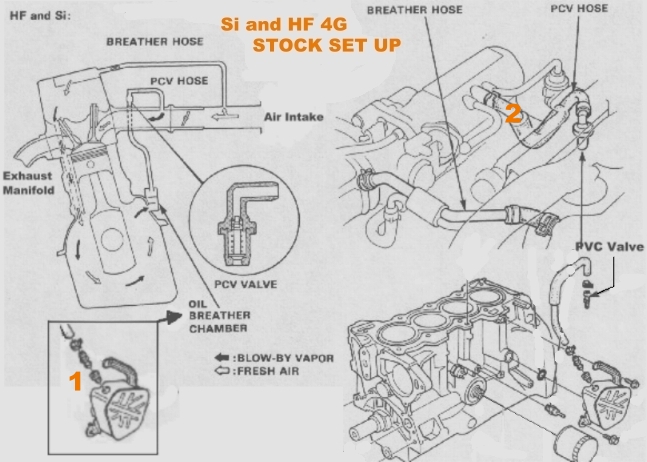

OIL CATCH CAN

As Larry said, "The purpose of the catch can is to separate more oil from the crank case vapors. The presence of oil in the intake charge is an open invitation to detonation. This system will allow a typical blower engine to tolerate about 3 PSI more boost than the stock PCV system.

Honda engines were designed to be operated with a closed PCV system intact! You can't just vent the backside of the engine and/or the valve cover to atmosphere and negate crankcase pressure at high power and rpm levels. If you're planning to do it that way, drill a couple 1" vent holes in the valve cover (preferably near the large drain holes), weld in a couple 1" diameter tubes, and run a 2.5" - 3.0" breather on each. You could also connect hoses to each and merge them into a common tank with two breathers for vents. You'll still need to vent the block to a tank with another breather.

The entire engine is configured to have suction placed on the crankcase and the ventilation of the valve cover using the little K&N filter is barely adequate for those purposes. The passages from the block to the head were also configured for minimum vapor flow, once again, because the system was under vacuum from the PCV valve. The upper valve cover vent was also configured to help purge the vapors and dilute them prior to consumption by the inlet tract of the engine.

None of this means a hoot, unless you're serious about ridding your engine of excessive crankcase pressure and, or reducing oil contamination in the cylinders. When an engine's crankcase breathing is designed to have a vacuum drawing the vapors out, you either have to use a vacuum source (engine, or pump), or ventilate the hell out of the engine. There's no cheating or getting around the proper ways of doing it, period.

MOROSO tank does an acceptable job because it has the central tube with a couple baffles in it. That tube is essential to making the vapor travel down, then making a 180 degree turn, prior to traveling back up to the top and exiting via the PCV valve. If you don't make the trip complex enough for the oil vapor, it's not going to trap any. Conversely, if the trip is too restrictive (size-wise), the losses will be so high that the system won't work. I have modified MOROSO tank somewhat by placing 3 extra baffles as illustrated below. The baffles are made of the outer protective speaker grill that usually comes with the set but is never utilized.

Regarding the two upper (valve cover) vent connections, I do believe that they should travel to a slash cut tube in the intake induction tube. The slash cut tube should be at a 60 degrees angle and should face the airflow. You'll need to be careful with the one in the oil filler cap, as there's no baffling below it to prevent divert contact from oil. If you want to see what I'm talking about, just remove the cap while the engine's running sometime."

![]()

THE SMALL THINGS

I used paper cups for bolts. Each component was assigned to one paper cup on which I wrote a little note where the nut or a bolt goes. I guess zipp lock bags will do as well. Moreover, get yourself a lot of shop rags. You'll need a lot. Don't even attempt to do any work without the Honda OEM Service Manual. Overall, I think this is a nice project that can be done by someone that does not have much experience with auto mechanics. Take me, I'm in Nuclear Medicine, and I guess I know more about car audio than auto mechanics and I did the swap practically all by myself!!!! It was fun!

PROBLEMS

If there are any problems that you may encounter in the long run it'll be with the engine tilting toward the front of the car. This slight "front sagging" is due to the way drive's side mount is mounted onto the VTEC block. What you can do to help is to firm up the mount (front tranny one). It'll raise the front a bit. You can simply use the the Energy Suspension engine mount insert. Use the front tranny insert at its proper location, but do not insert the one near the fire wall but instead place the inserts at the front driver's side mount. It fits! You won't wont have any problems. There are NO increased transfer of vibrations at 600rpm and up. You will feel it if your idle drops to 400RPM. If you're thinking to insert the inserts after the engine swap, to insert the front tranny mount inserts you'll have to separate the B pipe from the header to remove the long bolt.

Moreover, the clutch grabs at the very top of the pedal release despite the fact that there is no more free pray to work with. Hm, maybe it is a good idea to use 92-95 clutch components with the VTEC block. Finally, the timing belt is slightly rubbing on the driver's side engine mount. It's a good idea to shave some of the metal off to provide some more clerance for the timing belt.

Created on July 1997

Last modified on Jan 16, 2003.