Now it's ready to unload. We used an

engine hoist to lift the business end,

as my son and his friend lifted the tail.

Then I just drove out.

On the right of this photo, you can see

the jig used to support the engine.

|

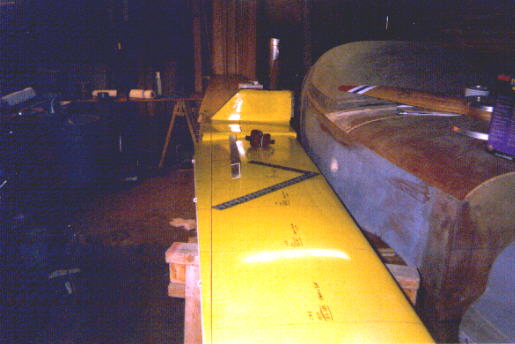

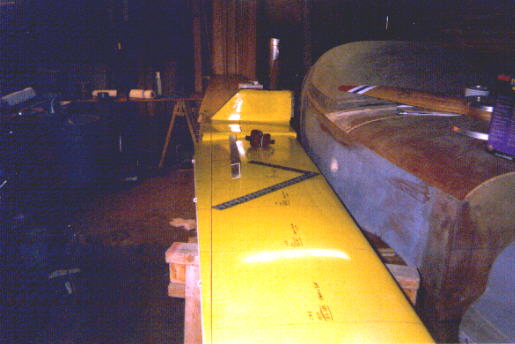

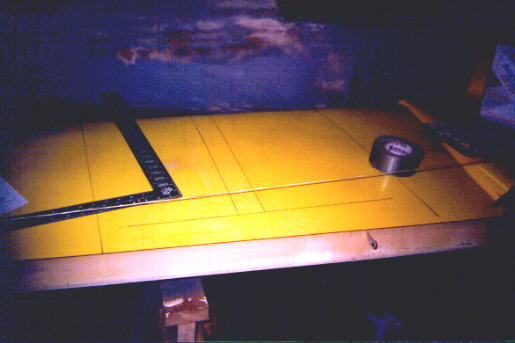

A string line was established, 90 degrees

to the centerline. Since neither the

leading edge nor the trailing edge are 90

degrees to the centerline, it was important

to have this reference to align the gear

boxes properly.

|

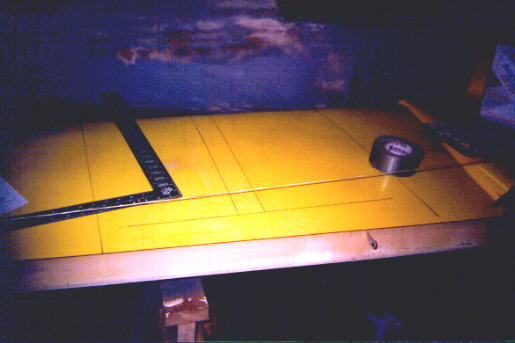

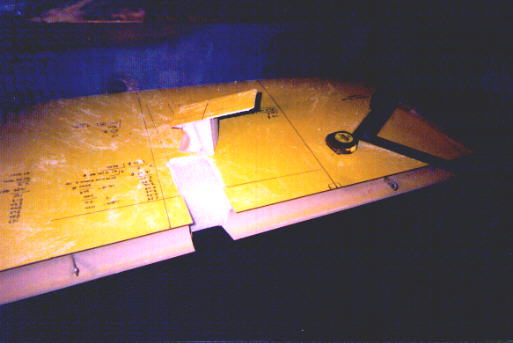

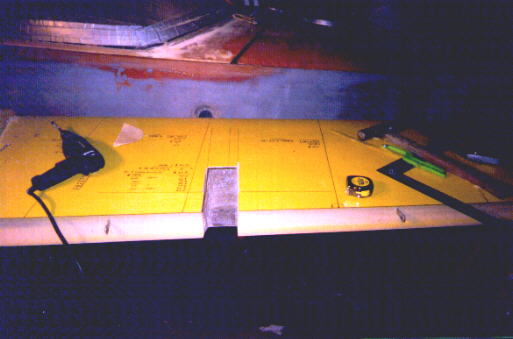

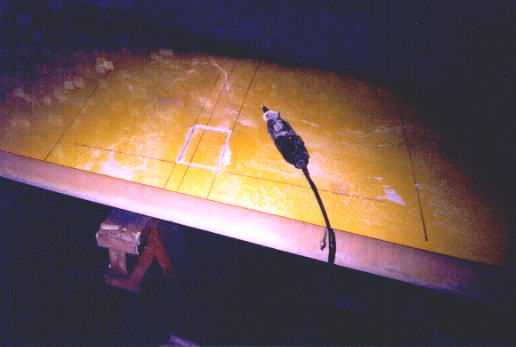

With the string line in place, I used a

framing square to lay out the cuts for the

gear leg box. The stray markings on the

canard's surface were used to define the

loading stations for the stress test.

|

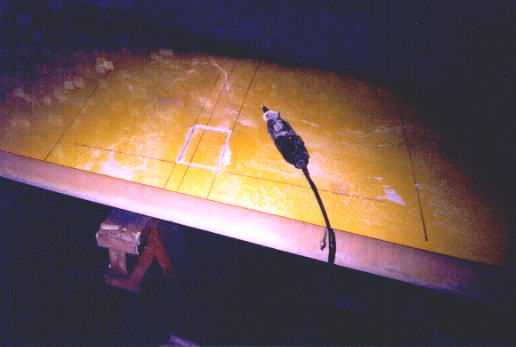

With the cut lines marked, I needed to find

the edge of carbon fiber spar cap. I did not

want to cut into this at all, so I very

carefully used the Dremel tool to grind

away slowly, until the dust became black.

|

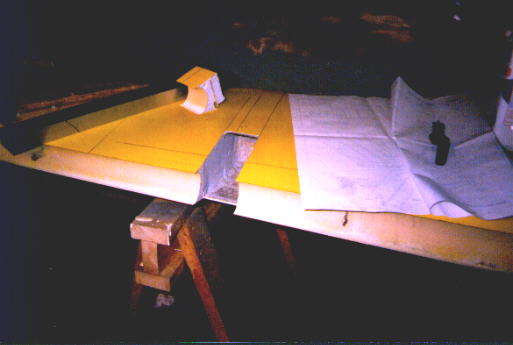

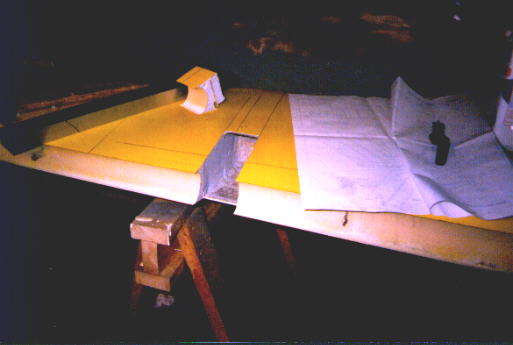

Being very conservative at the cutting

stage, I did not cut through the drag spar

as instructed. I was hoping that I could

insert the gear box without cutting into

the spar. Here, I used a claw hammer to

pry the scored glass from the foam core.

|

Once the glass was removed, came the

chore of removing the foam from the

cavity. I tried to use a stone on

my Dremel, but it just gummed up as it

melted the foam, rather than grinding it.

|

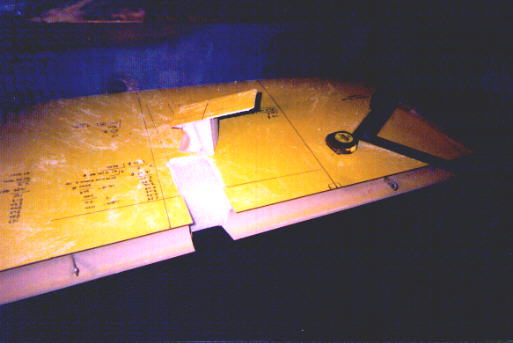

I then chucked up a 3/8" drill bit, and used

the side of the bit as a rotary rasp to

remove the foam. This worked GREAT!

It also allowed me to reach all the way

back to the main spar, and with care,

it produced a rather nice cut.

|

At this point, I surrendered to the

instructions from Viking, and removed

the drag spar. I could not get all the

way to the main spar with my drill if I

had left it in place.

|

Here's a view of the hollowed out

section, seemingly ready to receive

the gear leg box.

|

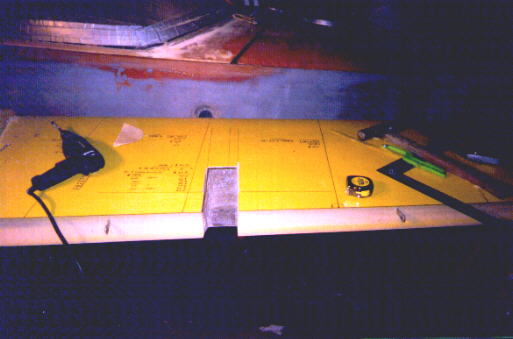

Happy with the progress on the first hole,

I was more aggressive with the second

hole. I cut out the drag spar right away.

|

The 3/8" drill bit was returned to service,

removing the foam from the second hole.

|

After I was happy with the removal of

the foam, I removed the elevator

faring to expose the area of the drag

spar to be reinforced. Then I removed

the paint and filler from the area to

be patched.

|