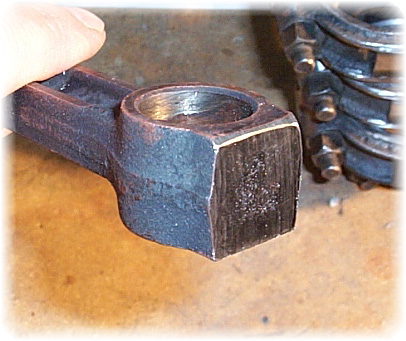

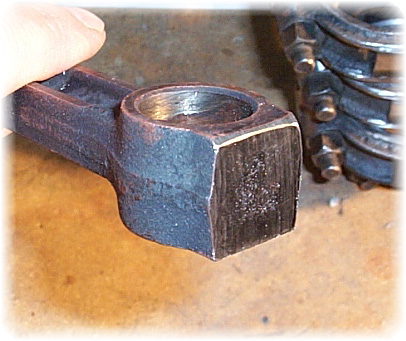

Looking at both ends of the

connecting rods, one can see the balance pads. This is the

area on the rods which was forged into the part, specifically to

be removed as needed to balance the rods one to another.

The image on the left is obviously the small end (piston end) of the connecting rod, and the right

image is the crank end. The piston end has been ground down

at the factory. Since all the rods weighed about the same (within

3 grams of one another) and only the piston end was machined, I

assume that this was the factory practice, to simply weigh the

rods and remove weight from one end only.

Following Richard Finch and Bob

Sutcliffe's advice, I balanced each end separately.

Here's the completed stack.

|

Rather than just grind more from the top of

the pad as the factory did, I removed most of the mass from

the corners, rounding the pad quite a bit. This was

pretty straight forward.

All in all, not much material had to be

removed from the piston end of the connecting rod.

|

| Notice how the second from the top, and the

bottom rods don't have any work done to the piston end balance

pad. That's because these two were the lightest, at 113

grams. The other's were anywhere from 115g to 123g. |

|

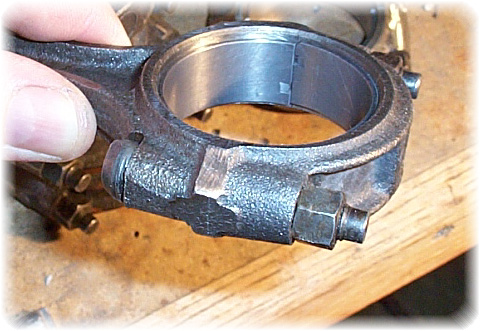

On several of the crank ends, I chose to

not use just the balancing pad for weight removal. In fact if

I had, I would have not only run completely out of material to

remove, but in my opinion, I would have weakened the

cap. So I opted to remove excess material before starting to

grind on the balancing pad. I did this to every rod,

even if only a gram or two was to be removed.

Also see page 15 of Clark's "Otto"

catalog to see where they remove material to lighten rods.

The left image shows a rod which has not been

ground. The right image shows one which only a little bit of

weight was removed. The material removed is part of the excess

which Bob removes when he lightens rods, so I felt it was safe

to start here. |

|

This rod needed just a bit more weight removed than

the rod in the previous photo... |

|

...but this one needed a bit more. This is

about as far as I would go, before getting into grinding on the

balancing pad on the.

Any and all grinding was followed up with some very

fine sanding (polishing) to reduce the stress riser effect of the

scratches left by the grinding wheel. |

|

On the left is a stock rod bearing cap.

On the right is one which has been ground down by about 1.5 - 2 grams.

|

This one however has a good 4-5 grams

removed. Notice that I dished out the pad, rather than just

grind it off along with the ribs which make up the "C" section

beam. |

|

And this is the finished stack. The top one

has just a little removed, the next two substantially more,

the next two none, and the bottom one, a whole bunch.

I started out with the small ends weighing anywhere

from 308g to 316g and the big end weighing 113g to 123.

Now the small ends weigh within 1g of 113g,

and the big ends weigh within 1g of 305g.

All together I took 10g off each rod. |

|

|