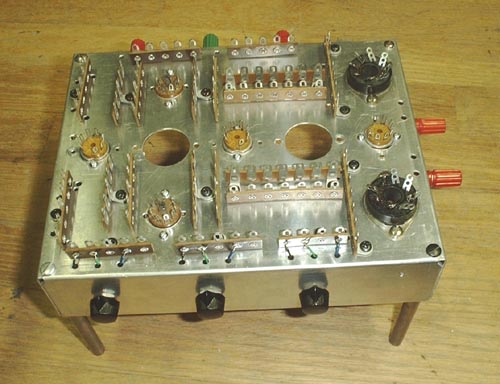

There are a great many ways to breadboard vacuum tube circuits. After years of experience and some recent testing I have concluded that the best way is to solder wires and small components to terminal strips. If you have not already read the page comparing the various methods of breadboarding I suggest you click here.If after reading that page you decide to build a breadboard like this one, here is how to do it. First of all it is not necessary that you exactly duplicate what I have done. In fact this is just to give you ideas which you can pick out parts to build and parts to leave off or you may even expand on this project. Mine is built on what is left of a 12 x 7 x 4 inch Bud utility box. I say what is left because it is recycled from an earlier project. Since one picture is worth a thousand words (one of my colleagues once presented a mathematical proof of that) here are a couple of thousand words.

The circuit constructed on the breadboard is a three tube radio. It is basically the first three tubes of an All American 5. As you can see it's mainly terminal strips and tube sockets. The terminal strips are likely to stay as they have been installed but the tube sockets can and will be changed to accommodate the particular project at hand.The 5 holes on the right side of the left hand view are all identical and are for octal tube sockets although mounting plates for IF transformers will fit, as you can see. Can type filter capacitors will also fit.

The 5 holes on the left will accommodate 7 or 9 pin miniature sockets. The bottom most socket is a 7 pin and the other two are 9 pin. Close inspection of the picture will show that the holes for the 7 pin socket partially overlap the main cutout. It is absolutely necessary that you drill the small holes before punching out the larger hole.

As you can see in the right hand view two pieces of angle aluminum are mounted across the top and bottom, as shown, to strengthen the chassis. Why didn't I use the other half of the box? It had been too badly cut up for the earlier project. Also shown on the back panel are the binding posts, BNC and phono connectors for power and signal in and out. Wires from these run up through small grommets and are soldered into the eyelets of the terminal strips. The front panel has room for 4 pots and a variable capacitor salvaged from an All American 5 radio. Two of the pots are 500 k ohm audio taper and the other two are 100 k ohm linear taper. Two 2 - 1/2 inch plastic spacers are mounted to the angle aluminum which is on the left side when the breadboard is in its normal position. As shown in the photo below these are to hold the home wound coils used in radio circuits.

It took about an afternoon and an evening to build the three tube radio. That's not too much longer than it would have taken with some sort of solderless breadboard. The problem is that it works so well that I don't want to take it apart.But what if I built the other breadboard and found, as you did, that it's not as good as it seemed? Do what I did. Take the IC socket breadboards off of the chassis, punch holes for two more mini tube sockets and mount some terminal strips in the empty space.

When I decided to do this I had already stripped the binding posts off to use on the new version. I have replaced some of them but have left some holes open. That actually increases flexibility. Because the center row of holes permits alternating mini tubes and IF transformers it seems like a better solution for the three tube radio.

Use your "Back" button to return to where you were.

Thank you for visiting my page at Angelfire.

Please come back and visit again!This site begun March 14, 2001

This page last updated September 16, 2002