I got this part fairly flat but the surface is still rough. Most of this will be hidden behind the brake master cylinder, so it shouldn't be very visible. A touch of body filler may be applied here.

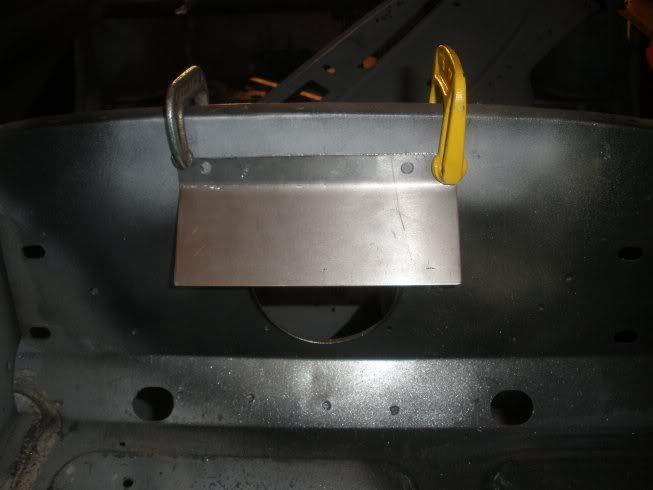

This is the water deflector inside the air intake box. The old one was removed due to the usual rust hiding behind the joint.

While placing the first weld I realized I had the welder adjusted wrong, but it still didn't sound right. I looked at the guages on the bottle and discovered 0 pressure. I must have left valve on overnight...Oops.

That said, the welder got put away until I get the bottle filled.

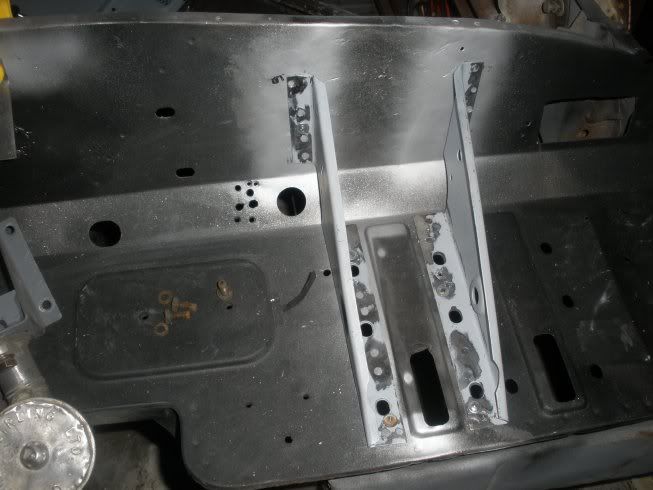

I installed the master cylinder support brackets with self tapping screws for fitting.

Checking clearances and looks with the master cylinders.

Master cylinders and rebuilt pedal assemblies. Cleaned and stripped to the bare metal, protected with Por-15.

Years ago I had a friend with metal lathe and a passion for building anything. He turned some pins for me out of some hardened steel, and they match the old ones perfectly, though without the corrosion pits.

Additional view. The photos hide the imperfections wonderfully. Too bad it's not that easy.

A foreshortened view. If you look along the rain chanel here you can see a dip in the middle where the split metal is.

Gap between the body and the hatch. It's quite close now.

Still gotta figure out exactly how to handle the crack in the middle.