First remove the 3 screws that hold the plastic ccase on, should be allen screws some are philups.

Pull the plastic casing off and while pulling rotate the case COUNTER CLOCK WISE, this helps not to disturb the recoil. (BE VERY CAREFUL HERE!) USE SAFTY GLSASS'S

after the plate is off inspet the ones way notice how its on, also DO NOT remover the 4 screws on the aluminum back plate. we dont need to disturb this.

Again inspect the oneway bearing, NOTE the silver band, this fits against the metal plate.

Remove the mechanisim and lay it on a flat surface faceing down, note the direction the coil is wound

Still with me so far?

Ok next remove the button from the handle, untie the rope. set the button aside you will need it again later.

As you can see in the picture the button fits into the square section of the handle

remove the case the rope wraps around, this is the tricky part try not to disturb the coil. ***THIS IS THE DANGERIOUS PART ALSO***** BECAREFUL****

here you can see how one end is tucked up into the corner of the plastic housing and the other is bent in the center. this is how it needs to be if its broken bend the recoil into the shape that fits the rope holder. this isnt a hard job it just takes time.

this is why i dont use pull starts, they fail at the worst times. you never kinw when they go. when they do they go sudden.

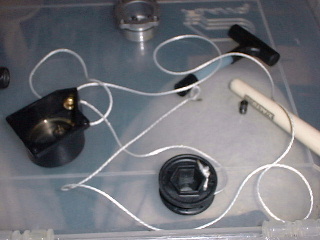

determine how long you want it to be and the size of the replacement line/rope. keep in mind that the more you use or the larger it is the less it will fit on the spindle. to much will rub and drag the recoil. this can cause problems also.

I use spider wire, you can get it at K-mart or most fishing supply stores. any line made from spectra type material is the best. they say that spectra line is 100 times stronger than steel! for its size and weight. its GOOD STUFF!

Use any size over 50 pounds atleast. i think im using 100 pound.

Here you can see the size of the wire/rope

wrap up the rope around the spindle, notise the direction that i wrapped it up. this is how it needs to be to recoil the rope back into the case.

after its wrapped up feed it threw the brass ilet.

after its threw rewrap any extra thats left.

Pull the rope out about 5-7 inches and rewrap it. this keeps tention on the handle so that it sits up off the engine.

Feed the line threw the plastic spacer then threw the rubber tube. here you can modify it to any length. this could be handy depending on the car, body style or the placement of the pull handle. you can use fuel tubing and thats what i used.

feed it threw the handle and tie it around the button, push the button back into the handle and test it. ****CAUTION*****

**********CAUTION*********

If and when you test it keep it flat on a table or keep force on the spindle or it will pop out of the case like mine did.

dont pull it to fast and be an idiot like i did. now i have to recoil the metal recoil. this is a hard part so becareful.

Ok if you happen to be an idiot like me and yank on it when its out of the engine and not hold the spindle into the housing, hers what you do.

First uncoild it,from its WHACKED out state unknot it and get it laying flat.

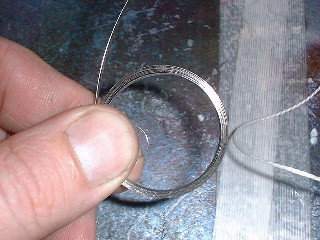

Hold it by the center coil and pull the outer coil.

This tightens the coil and wraps the recoil back up, im sure there is other ways to wrap it but this is what works best for me.

Keep wraping it till it gets to the size of the housing, when it gets small enough it starts to get very hard to hold.

this is where a good small set of needle nose pliers can come in handy. mine are jewlers pliers i picked up from hobbyloby. very small tip and good quality. i think Xacto is the brand ive had em since ive been in this hobby.

insert the spindle back into the housing and make sure that you have the right amount of tension on the rope to keep it up off the engine and the chassis of the car.

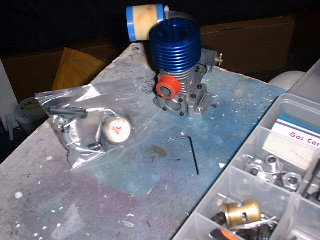

Now that your finished, put it bag into the plastic bag. put the nonpullstart plate back on and go get a starter box, :) like i did. or you could save all the headache and throw the housing away and use the drill. find a socket that fits on that oneway nut, hook the socket to your drill and go have some fun!