picture courtesy of http://www.bensrallypage.com/forsale/basiliere_legacy.html

STOCK SPECIFICATIONS:

2.2L SOHC, turbocharged, non-intercooled, 4-cylinder boxer engine

5-speed manual/4-speed automatic AWD transmission

Viscous center and rear LSD (manual)

Clutch-type center differential and rear viscous LSD (automatic)

Sport-tuned suspension

Brakes: 10.9

Model Year Technical Specs at the Legacy Archives.

Subaru introduced the Subaru Legacy Sport Sedan to the US domestic market for the 1991 model year. The Sport Sedan was a 2.2L 4-cylinder, SOHC, turbocharged, non-intercooled variant of the JDM Legacy (which was fitted with a 2.0L 4-cylinder, DOHC, turbocharged and intercooled engine to compete in the World Rally Championship). The USDM engine produced 160hp @ 5600rpm, and 181lb/ft of torque @ 2800rpm. Pretty modest numbers for a turbocharged car. This is due to the lack of an intercooler and factory-limited boost at 8.7psi (http://www.xmission.com/~dac/library/turbo_info.htm).

ENGINE BLOCK (information and pictures adapted from: http://www.sdsefi.com/air17.html). The engine has a closed deck providing a much stiffer cylinder assembly and better head gasket sealing. Cast iron liners about .125 thick are cast right into the aluminum. The block is a precision medium-pressure sand-cast unit, which affords the block the necessary rigidity to withstand closed decking (SAE technical document #890471). The majority of Subaru blocks are instead high-pressure, die-cast aluminum, and although stout, do not have the same rigidity to withstand high boost pressure. This is due to high-pressure casting forcing air pockets into the aluminum mass as it cools. The result is a block with more localized stress areas within its structure. Conversely, a medium-pressure cast aluminum crankcase will be denser and more rigid. Subaru spared no expense in the development and manufacture of the block as the medium-pressure casting procedure is quite extensive, and more importantly, expensive, when compared to the typical high-pressure castings (xephyr).

It should be noted that the increased density of the M-P aluminum block has the propensity to retain heat to a greater degree than its H-P brethren. Subaru has addressed this issue by incorporating plenty of coolant passages in the head to block area and a wide bore spacing, which allows for higher boost levels to be maintained. The coolant flow path has split passages in the block to force coolant from the lower block, through the head and back into the upper block. This setup uses natural convection to aid direction and efficiency of coolant flow.

Closed Deck Block

Oil Jets/Main Center Bearings

Engine Block Half

The turbo engine has piston oil jets to cool the piston domes under boost. In order to feed these jets (and the turbo) Subaru utilized a higher pressure, larger flow oil pump (xephyr). Extensive ribbing in the casting on many of the water and oil passages help to dissipate heat from these areas as well. The block halves are attached with ten 10mm bolts and seven 8mm bolts, creating a very rigid design. The 3 center main caps which span the cylinder bores are 2 inches thick and carefully radiused to preclude any chance of cracking.

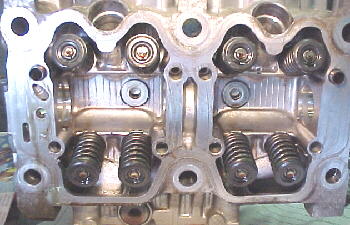

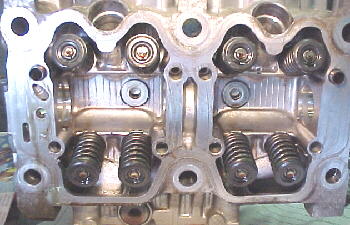

CYLINDER HEADS (information and pictures adapted from: http://www.sdsefi.com/air17.html). The heads are of a compact, SOHC design, and provided more-than-adequate cooling passages. Six 11mm bolts hold the heads to the block. These are very long and go right into the base of the block so that there are less localized stresses present in the block deck. The intake valves measure 31mm and the exhausts are 28mm. These stock specifications are adequate for the stock boost levels, but could use some enlarging for higher power applications. Subaru’s intention with this design was to provide much better off-boost throttle response and midrange power.

“Anyways, you are correct in assuming the heads aren't stock. They EXTREMELY ported and polished, aftermarket valves, three-angle valve job, dual valve springs, and titanium retainers. At one point I had bigger cams. They were from the same place that does Cobb's cams. Those cams aren't in the heads now because they disintegrated. Yes, you heard that right. The welds on the lobes started eroding off after several months, and one of the lobes actually chipped and popped a shim out and caused catastrophic damage to the head. It took a long time to fix that mess. I concluded the welded cams might not have been hard enough to withstand my super stiff valve springs. With the stock heads, there is a significantly crisper and responsive low and mid range. With the ported heads there is a MUCH better top end (after 5000 rpm), but the mid range suffers, and the low-end response really suffers. With the ported heads and stock cams, I hardly noticed a difference without the bigger cams. After you get to a certain HP level, it becomes difficult to distinguish an extra 10-15 HP. It did seem however that the stock cams gave me a more tolerable low end with the ported heads (xephyr).”

Cylinder Head (top)

Cylinder Head (bottom)

PISTONS (information and pictures adapted from: http://www.sdsefi.com/air17.html). The pistons are pressure cast, molybdenum coated, dished pistons with a 8.0 to 1 compression ratio. The pistons are of the “thermalflow” variety, which withstand the high thermal stresses of turbocharging. Although the are not forged units, they are the next best thing (xephyr). The pin is 23mm in diameter and has a massive .190 wall for rigidity. The turbo pin is somewhat longer than the naturally aspirated pin, however, the piston dome on the turbo piston is thinner than the naturally aspirated piston at .145 inch vs. about .210. There is definitely some room for improvement here. However, the stock pistons have been tested to withstand at least up to 350 crank hp.

ej22T piston (right) vs. N/A ej22 piston (left)

ej22T piston (right) vs. N/A ej22 piston (left)

CONNECTING RODS (information and pictures adapted from: http://www.sdsefi.com/air17.html). The connecting rods are well-designed forged alloy steel. They are short and stiff, measuring only 5.25 inches center to center. They are fitted with high quality 9mm ultra fine thread bolts. Bronze pin bushings are pressed into the thick walled eyes. The stock con rods, although forged, are thinner than your typical aftermarket forged rods, however, like the pistons, these rods have been known to withstand up to 350 crank hp.

ej22T connecting rod

CRANKSHAFT (information and pictures adapted from: http://www.sdsefi.com/air17.html). The EJ22T’s crankshaft is forged and heat treated steel and weighs only 20 lbs. Total length is only 13.5 inches. The short stroke design gives about .750 inch of crank pin vs. main journal overlap, making it very stiff. Oiling is reasonably well thought out. The crank fillets are rolled for low stress and fatigue resistance. Journal diameters are 2.36 mains and 2.05 on the rods. The crank is fully counterweighted, contributing to the overall smoothness of engine operation.

ej22T crankshaft

TESTAMENT TO ENGINE RELIABILITY!!

"My only engine failure involved an ej22g engine experiment I was pursuing for a short time. The experiment I refer to involved my attempt to find out what the limits of the engine were. It started with an ej22g with 150,000 miles from the junkyard. First, I ran it for weeks at 27-30psi. Second, I over-revved it to 11,000rpm twice, by shifting from 2nd gear I redlined to first (by the way, this shift can only be done with a dogbox). After having no failures, I finally took it to Second Creek Raceway. The track is a 1.7mile circuit track, with hills, chicanes, all kinds of turns, and so forth. I drove the piss out of it for 20 laps straight (over twenty minutes straight), shifting at 9000 rpm, heating the hell out of it, and pummeling it with tons of boost. Eventually, I spun the number-2 rod bearing. After tearing down the engine, inspection of the engine revealed that other than the bearing, the rest of the engine was in perfect shape!! Furthermore, the failed rod bearing was more than likely caused by damage sustained from the 11,000rpm incidents (xephyr)."

TRANSMISSION. The transmission was also considerably beefed up for turbocharged use, when compared to the naturally aspirated subaru offerings:

"To handle the power, both the five-speed manual and four-speed automatic transmissions have been modified. All of the five-speed's gears have been shot-peened, and the mainshaft bearings have been changed to a 'double-angular' design. The gearbox case was also modified to accept a hydraulic clutch release fork, shaft and cylinder because company engineers felt a cable-operated design's pedal effort would be too high for this. (This change also prevented use of Subaru's "hill-holder" feature.) Also modified were the flywheel, pressure plate, clutch disk and pedal box. However, the changes do nothing to help damp the low frequency vibration and growl endemic to Subaru's flat engines, something the automatic accomplishes with ease. Thus the five-speed's refinement levels are lower." (http://www.xmission.com/~dac/library/turbo_info.htm)

All of these engine and transmission overbuilds lend themselves to a very moddable streetcar . . . and that's my lead-in to my own Turbo Legacy . . .