4.6L Three-Valve Ford Modular V8 Engine

Home | Intake | CMDP | UDP | Exhaust | Suspension | Interior | Aerodynamics | Parts | Dyno | Bolt Ons | Engine | Coyote SwapThe 4.6L three-valve engine fitted in the 2005-2010 Mustang GT is an evolution of the ultra-reliable 260hp & 302lbft 4.6L SOHC Modular two-valve per cylinder PI engine fitted in the 1999-2004 Mustang GT. Thanks largely to a new lightweight aluminum block casting, new higher-flowing cylinder heads with three valves per cylinder (two intake, one exhaust), a higher compression ratio, and the introduction of variable camshaft timing (VCT), Ford extracted an extra 40hp & 18lbft from the same cylinder displacement. These upgrades gave the three-valve engine the sparkle that the two-valve engine lacked above 4000rpm whilst increasing torque output across the rpm range, thus allowing Ford to raise the rev-limiter from 5800rpm to 6250rpm. The three-valve engine is also very reliable but there were nevertheless some flaws that left room for improvement, and upgraded parts are available to make it virtually bulletproof.

Stock Specifications

Bore: 3.552" (90.2mm)

Stroke: 3.543" (90.0mm)

Displacement: 280.8ci (4601cc)

Compression ratio: 9.83:1

Deck height: 8.937"

Rod length: 5.933"

Piston compression height: 1.220"

Deck clearance: 0.0125"

Head gasket compressed thickness: 0.036"

Quench height: 0.0485"

Head gasket bore: 3.622" (92.0mm)

Head gasket volume: 6.1cc

Combustion chamber volume: 51.0cc

Piston dish volume: 6.0cc

Deck clearance volume: 2.0cc

Block

The Romeo cast OEM 3V aluminium block is reputedly capable of handling 1000 crank HP without failure. Simple deburring of sharp edges eliminates stress risers that can lead to crack formation, thus allowing the block to handle as much as 1500 crank HP. For higher HP levels, the much-vaunted Teksid block used in the '96-'98 4.6L Cobra 4V engine is recommended. Alternatively those looking to build a larger displacement stroker engine can opt for the 65lb heavier 3.700" bore Boss 5.0 Modular cast iron block (Ford Performance part no. M-6010-BOSS50).

Crankshaft

The 3.543" stroke OEM nodular iron 6-bolt crankshaft is reputed to handle up to 800 crank HP without failure. For higher HP levels, a forged steel crankshaft is recommended. This offers the opportunity to add displacement by opting for a stroker crankshaft (3.650", 3.750", and 3.800" strokes are available). A +0.002" cylinder hone of the OEM block, combined with a 3.800" stroker crankshaft, results in a displacement of 302ci or 4942cc (same as legendary pushrod Windsor 5.0), while a Boss 5.0 Modular block allows a displacement as high as 327ci or 5356cc.

Connecting Rods

There have been no reported failures of OEM sinter-forged powdered-metal I-beam rods in naturally-aspirated 4.6L engines that have revved up to 7600rpm in very short bursts (e.g. drag racing, dyno runs), but this rpm limit hasn't been tested during prolonged high rpm use (e.g. road course or endurance racing). Fortunately it's easy and inexpensive to upgrade to OEM Boss 302 forged steel rods (Ford part no. CR3Z6200B) that'll withstand up to 8500rpm at the stock 3.543" stroke.

When subjected to the elevated cylinder pressures of forced induction, the OEM rods have a tendency to bend or break. Engines fitted with a supercharger are effectively limited to ~450rwtq because the drivebelt applies tension on the crank snout and induces additional harmonic vibrations, whereas an exhaust gas driven turbo is more forgiving and allows up to ~500rwtq. Nevertheless, a set of forged steel rods is recommended to reduce the risk of catastrophic engine damage.

Pistons

OEM hypereutectic aluminium pistons have a low expansion rate that allows a tighter piston-to-bore clearance in order to minimize hydrocarbon emissions, but can shatter like glass when subjected to detonation resulting in catastrophic engine damage. In forced induction applications, forged aluminium pistons are likely to melt or crack rather than shatter when subjected to detonation, thus sparing the rest of the short block from severe damage. Pistons should preferably be upgraded together with the connecting rods and balanced with the crankshaft to eliminate unwanted vibrations.

Oil Pump

The OEM gerotor oil pump is a durable unit that operates reliably in naturally-aspirated and mildly boosted engines. However the powdered metal gears are prone to fracture and cause a catastrophic loss of oil pressure either when subjected to high boost pressures from a belt-driven supercharger, and if the engine is allowed to bounce off the rev limiter. The aluminium backplate can also flex at sustained high rpm, causing oil pressure to leak out of the pump housing. The OEM '13-'14 Shelby GT500 high pressure oil pump (Ford part no. DR3Z6600A) has a steel backplate and is an inexpensive upgrade that's capable of handling up to ~800 crank HP. For extra insurance, billet steel oil pump gears could be swapped into the aforementioned oil pump, though aftermarket pumps with billet gears e,g, MMR Hurricane #450460 are also available.

A new OEM 3V oil pump pickup tube (Ford part no. 4R3Z6622AA) can then be mated to the GT500 oil pump. If the '07-'14 GT500 oil pump pickup tube (Ford part no. 7R3Z6622AA) is used instead, the OEM 3V windage tray can be replaced with the '13-'14 GT500 oil pan gasket/windage tray (Ford part no BR3Z-6710-B).

Oil Pan

The OEM 6 quart oil pan is adequate for normal street duty but naturally-aspirated engines with a higher rev limit (7000+rpm), and engines with forced induction, will require a higher capacity oil pan in addition to a higher volume oil pump to ensure adequate lubrication and cooling of engine parts. The '13-'14 GT500 8.5 quart oil pan (Ford part no. DR3Z-6675-A) will fit directly onto the 4.6L 3V block with only minor clearancing of the '13-'14 GT500 windage tray required.

Moroso and Canton Racing also supply higher capacity oil pans with extra baffles and trap doors that provide better oil control in vehicles that are subjected to high fore/aft (strip) or lateral (road racing) g loads.

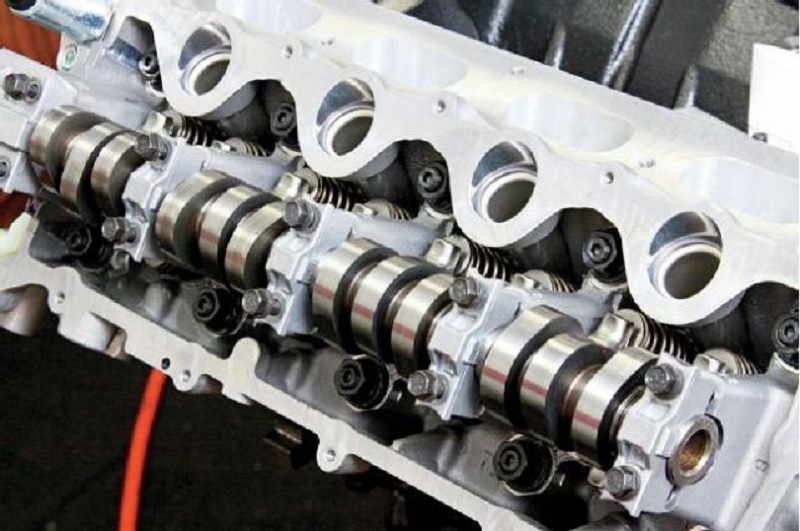

Valvetrain

The original factory camshaft phasers and rocker arms are prone to premature failure when oil changes are repeatedly extended beyond Ford's recommended intervals, when oil of poor quality or the wrong viscosity has been used, and when the engine is repeatedly thrashed. Ford Performance offers direct replacement parts that provide improved oil circulation for increased durability.

The thin gaskets on the OEM plastic timing chain tensioners are also prone to harden with age and perish, reducing oil pressure and flow to the tensioner's plunger. As a result, the timing chain will rattle especially from a cold start and at low engine rpm until oil pressure builds up. The Ford Performance camshaft drive kit includes new OEM tensioners but to prevent future failure, Felpro gaskets should be inserted as an upgrade.

These parts should be replaced on any 4.6L 3V engine at the 150k mile service if this procedure hasn't already been performed earlier.

Ford Performance Camshaft Drive Kit: M-6004-463V

Ford Performance Rocker Arm Lash Adjuster Kit: M-6529-3V

Felpro Timing Chain Tensioner Gasket Set: ES73226

OEM valve stem oil seals: 3L3Z-6571-DA (or Viton valve stem oil seals).

PQY Performance valve spring compressor: VSC07B.

Valve Springs

OEM valve springs (Ford part no. ER3Z-6513-B) were rated up to 6800rpm and 0.472" (12mm) of valve lift, allowing them to be retained when upgrading to aftermarket NSR camshafts.

However VSR and SPR camshafts require a valve spring upgrade. PAC-1233 valve springs are rated up to 0.550" of valve lift but since they are compatible with the OEM retainers/keepers, there's a significant cost saving.

SPR camshafts also require camshaft phaser limiters e.g. Comp Cams CCA-5449 or phaser lockouts to prevent piston to valve contact, and SPR camshafts with over 0.550" valve lift will require Comp Cams CCA-2612524 valve springs that are rated up to 0.650".

Spark Plugs

Three-valve engines built up to the end of November 2007 with black coil boots were originally fitted with 100,000-mile platinum copper 16mm spark plugs (Motorcraft part no. PZT-1F) built from two pieces that were prone to separate upon their removal from the cylinder head. Ford resolved this flaw by reinforcing the joint between the two pieces with spot welds on the latest OEM replacement Motorcraft SP547 spark plugs. The original 12mm one-piece spark plugs fitted to engines built from the beginning of December 2007 onwards with brown coil boots did not have this design flaw. The latest OEM replacement spark plugs for these engines carry the Motorcraft part no. SP509.

Cooling System

The stock '05-'10 Mustang GT cooling system is reliable and efficient enough for street duty and the drag strip, with the stock Motorcraft thermostat opening at 192*F (89*C) to maximize engine efficiency. However forced induction and road racing applications will require an increase in cooling system capacity to prevent overheating.

Ford Performance Aluminium Radiator M-8005-MGT

Ford Performance Cooling Fan Upgrade M-8C607-MSVT

2005-14 Mustang/GT500/Boss Modified Fan Resistor Pack

2007-10 Cooling System Update & Meziere Electric Water Pump Upgrade

Fuel System

Stock '05-'10 Mustang GT fuel injectors flow 24lb/hr @ 39psi and reach their maximum duty cycle at ~410hp or ~360rwhp. Naturally-aspirated applications above this power level will require an upgrade to '11-'17 Mustang GT/Boss 34lb/hr injectors, while forced induction applications will require an upgrade to Ford Performance 47lb/hr injectors (M-9593-LU47) at a minimum.

The stock returnless fuel pump flows 148lph (246lb/hr) and is adequate for all naturally-aspirated applications running on pump gasoline, including 3V stroker engines. However all but the mildest forced induction applications producing less than ~440hp or ~380rwhp e.g. stock 435hp Roush 427R, stock 435hp Saleen S281SC will at least require a Kenne Bell Boost-A-Pump (BAP) to increase fuel pump voltage and output. From ~600hp or ~520rwhp and upwards, dual Shelby GT500 pumps together with a Kenne Bell BAP are recommended.

4.6L Three-Valve vs 4.6L Four-Valve

4.6L Three-Valve vs 4.6L Four-Valve

Both the '06-'09 Mustang GT's 3V engine and the '03-'04 Mach 1's 4V engine peak at roughly 270rwhp & 290rwtq in stock form (not surprising since they were factory rated at 300hp/320lbft & 305hp/320lbft respectively), and the HP/TQ curves overlap from 4200-5200rpm. However the 3V engine outperforms the 4V below and above that rpm range despite having a lower cylinder head flow (235/159cfm vs 266/175cfm @ 0.500" valve lift) and compression ratio (9.8 vs 10.1). How does the 3V engine achieve this?

The party trick is the variable camshaft timing (VCT) system. Ford made it simple but effective with a single overhead camshaft (SOHC) per cylinder bank that has fixed intake/exhaust valve opening durations, a fixed valve lift, and a fixed lobe separation angle, so only the intake/exhaust centerline angles are variable. From idle to 3750rpm, the cam timing remains fully advanced at WOT thus optimizing lower rpm torque production. Above 3750rpm, the cam timing is progressively retarded up to a maximum of 9 degrees at 5750rpm. This adds an extra 8hp peak-to-peak, broadens the torque curve, and carries near peak HP all the way to 6200rpm.

Stock Cam Specs

Stock Cam Specs

Advertised intake/exhaust valve opening duration: 248/279 degrees

Intake/exhaust valve opening duration @ 0.050" lifter rise: 196/221 degrees

Valve lift intake/exhaust: 0.439"/0.436"

Lobe separation angle: 114.75 degrees

Intake centerline angle (parked): 109 degrees

Intake centerline angle (maximum WOT retard): 118 degrees

Dynamic compression ratio: 8.47:1

WOT Cam Timing:

RPM STOCK (degrees retard)

500..........0

750..........0

1000........0

1500........0

2250........0

3000........0

3750........0

4500........2.5

5000........3.5

5750........9

6500........9

The stock camshafts produce more torque from idle to 4400rpm than any of the aftermarket performance units, so Ford really had their design properly optimized for a daily driver.

Cylinder Head Specs

Cylinder Head Specs

The valves on the stock 3V heads are generously sized with a valve head diameter of 1.338"(x2) intake & 1.476"(x1) exhaust. That's equivalent to a valve head diameter:cylinder bore ratio of 0.533 intake/0.416 exhaust.

Cylinder head flow:

Valve lift.....CFM..Intake..Exhaust..E:I Ratio

0.100".......................84........54........0.64

0.200".....................146......107........0.73

0.300".....................208......130........0.63

0.400".....................229......147........0.64

0.500".....................235......159........0.68

0.600".....................238......165........0.69

Intake port volume: 174cc

Exhaust port volume: 62cc

Combustion chamber volume: 51cc

Stock 3V heads are very efficient on the intake side where the port divides airflow towards two intake valves, whereas airflow is relatively poor on the exhaust side where there's a single exhaust valve and an undersized port. Ford compensated for this deficiency by equipping the 3V engine with dual pattern camshafts ground with a much longer exhaust valve opening duration.

Nevertheless stock heads allow N/A applications to make up to 415hp at the crank, while stage 3 CNC ported heads flow 280-300cfm intake & 190-200cfm exhaust @ 0.600" valve lift and allow N/A applications to make up to 480hp at the crank.