Gun Drill - Barrel making machines

This particular setup allows me to make my own barrels. I don't make a living out of this but it is nice to have the ability to make something that is better than what you might have to settle for.

The machine on the left is a gun drill. The gun drill bores a super accurate hole in the barrel. It is an older Monarch turning lathe that was converted over to hydraulic over electric drive. This was done to accomidate the fast speed needed. Over 12 feet long and solid cast iron base it was interesting to move!. The machine on the right is the button puller. Dual hydraulic rams pull the oversized carbide button through the barrel and a gear box turns it to give the twist.

Main Metal Lathe

High speed and accuracy is what this machine is capable of. Equipt with Digital Readout which helps speed things up. Getting guns in and out is nice but having the right machines to do the job well is worth the investment.

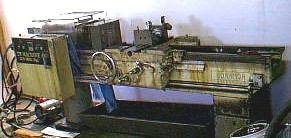

Secondary Lathe

Sometimes one is just not enough.... or we could say that two are better than one (actually I have 4 metal lathes). This tool room lathe is set up for various operations when doing more production work.

Milling machine

Milling out several of the parts made in the shop requires a good machine too. This smaller machine has been with me for quite some time and has served well. Of course these are just some of my main machine tools. These along with many, many smaller and hand tools, special jigs and more shop made speciality tools than I care to admit having are all part of the shop tooling. My shop is an approx. 2000 sq. foot modern facility. Why trust your investment to someone not willing to invest in what it takes to do the job right?