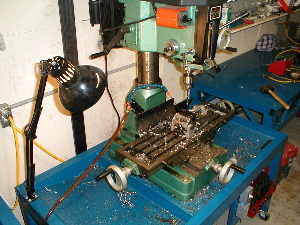

The tables are homemade the tools are not. Both tables have

a homemade coolant and sump system. I don’t plan to stay at

the present location for a lot longer.

The equipment will defiantly be moved a few times in the following

years. I made everything on wheels

for easy moving. I will hoist them

up on a flatbed trailer and strap them down when I move. I also like having the equipment on

wheels because I can roll them out to sweep under them. The mill table is made with supports

for drawers that will be added in the future. The drawer rails will mount on the 3 runners and slide in on

the ends. At the present location

I do not have room to open them anyway so I am not in too big of a hurry to

finish.

The mill and lathe I purchased from Harbor Freight tools. Harbor Freight imports the tools from

Asian under the Central Machinery brand.

Many other companies like Enco, Grizzly, Jet, Clarke, Etc. also import

tools of the exact same design.

Many times they are built in the same factory and the only difference is

the paint and label. Harbor

Freight can typically deliver it to your door for less than the other

companies. Their price is almost always less and they also offer free shipping.

There does not seem to be any importers that are guaranteed of consistent

higher refinement or quality but it is worth checking into at the time of

purchase. These imported tools are

not the highest quality or best tools around. I do believe they are a good value around for a hobbyist or

possibly small production use.

They are much less expensive and less quality than some of the

“professional” grade. I do someday

hope to purchase some high quality machines but these will work for now. For me

the price more than offsets the lack of refinement for what I need. I can get a shop full of machines for

the price of one of the others.

Some people highly criticize the imported tools I think unjustly. These tools can be great machines if

you fine-tune them where the Chinese did not. It requires a little work but there are many examples out on

the net of how to do such. I have

heard them described as a “kit” and I think that is a good way to look at

it. The lathes especially need a little

work. My mill is a great

machine. It is basically ready to

go out of the crate. Getting it up

on the table from the pallet was not an easy task. It weights about 690 lbs. I got 2- 4”x4”x1/4” steel angles about 8 foot long

each. I cut holes in one leg of

the angle and bolted it to the mounting bolts of the base. I leaned the mill over to get the nut

on the bottom side. This made four

handles protruding about 3 feet that could be grasped easily. I got about 6 of my buddies to lift it

up while another slid and positioned the table underneath. It worked well. If you do not have helpers then

dissembling it may be an option as well.

The Central Machinery 9”x20” metalworking lathe, not too big

but it works for what I need. The 7x10 mini-lathe is a very popular

tool for about ½ the price of the 9x20.

Unless you need 20” between centers like I did you might consider

getting it. I have not had a lot

of time to work much with the machine yet but am eager to use it. If you get it, before you engage the

threading half-nut be sure to deburr the lead screw key slot all the way

across. I did not do this and the

burrs stripped the zinc half-nuts.

Like I said it needs some refinement when you get it.

The mill and lathe were originally both on the workbench table seen in the right of the picture. Thus explains the very heavy construction. That got old quick. I decided they each need their own place and coolant system. I know that the coolant system is not really necessary but I find it very helpful. I am glad that I have it.