-

R/C

Model airplane

page_  |

| _________________________________________________________________________________________________________

BUI

BINH THO MD

__- |

|

|

|

R/C Model airplane

page

The

British & McDonnell Douglas AV-9M

Sea Harrier II ( version 2025-2045 )

Dr

BUI

BINH THO

|

|

Create : 2018 - new update 23 September 2024 |

|

|

My British & McDonnell

Douglas AV-9B Sea Harrier II

| Wingspan

: 50 inch ( 1260mm ) |

| Length

: 66 inch ( 1680mm ) |

|

High wing air foil NACA 3310.. |

|

Weight : 6.4 lbs |

| Engine :Two ducted

fan : One is 90mm12 balde fan with brushless motor DC 2200W

and Ducted fan 70mm 1200W BDLD motor . ESC 100A

and 120A |

| Contruction :

All wood air frame renforced by 5mm Depron hard foam & thin layer

silver solar film covered . |

| Radio : 2

receiver , 6 channel each |

|

|

|

This the

second time I had build and VTOL jet R/C airplane was the last powered by

ducted fan electric brushless DC engine .The origine airfoil of the

Sea Harrier is 3310 , the dehydral angle are

- 8 degrees .I decide

the NACA of this airplane was as same 3310 . . More light , strong material had

been used to contruct

this model airplane ;but the balsa wood is usually the good materiel to

made it. The contructions of this aiplane all are balsa wooden

air-frame renforced by 5mm Depron hard foam ; covered by thin alumium solar film . The gears

system ( see on the pic ) are quadricyclic , fixed ,

dirigeable and sprintable ( sea pic )

| |

|

|

|

|

| |

|

|

|

|

Wing : This is a 1005 square inch aircraft wing

made entirely of balsawood. The wing uses the NACA 3310 airfoil

with a shape and sweep angle similar to the AV 8B, but with

slight modifications to the wingspan, sweep angle, and

surface area (see figure). The two aileron system (see

figure) is independent, with each aileron controlled by a

2.5 kg/cm² servo, hidden inside the wing. The hinges of the

aileron and flap consist of four plastic pieces and are

installed at the middle of the rear wing bar. Multiple holes

in the wing's lamina have reduced the overall weight of the

wing. The flaps are independent and controlled by two 2.5 kg

servos, capable of reaching a 45-degree downward position.

The entire wing is covered with aluminum-colored solar

film |

|

|

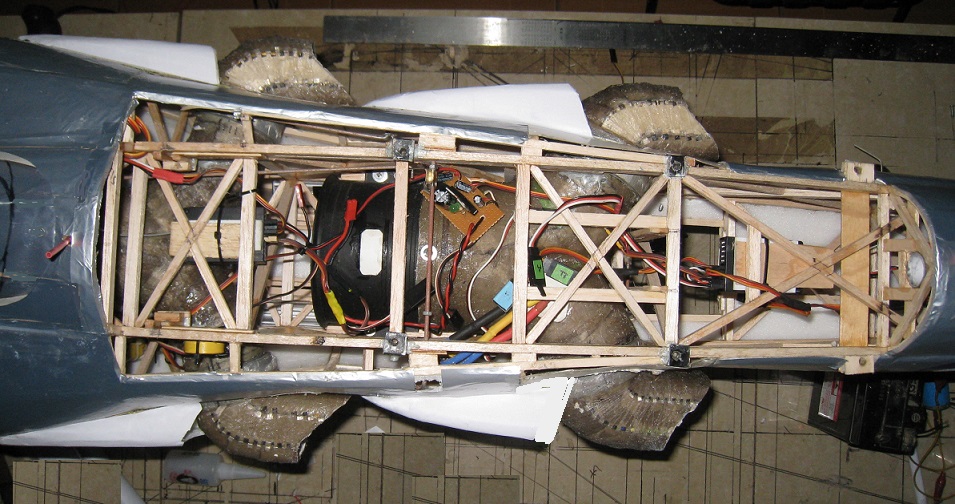

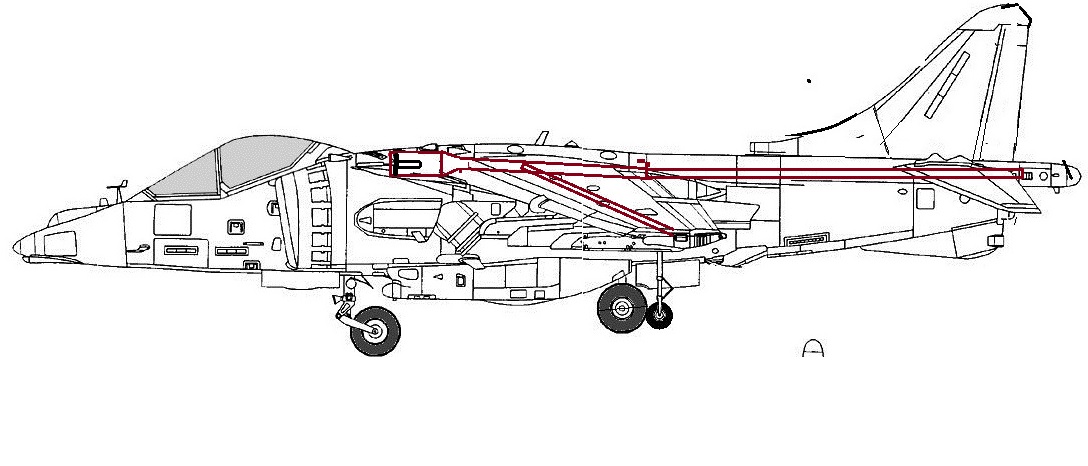

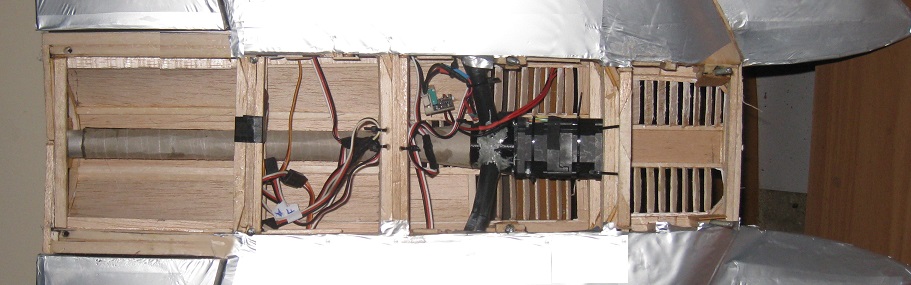

| Fuselage :The main

structure of the fuselage is an entirely wooden frame with four

main 6x8x1200 balsa hardwood beams reinforced with multiple

4x6mm wooden perpendicular and diagonal braces (see figure), and

the fuselage is reinforced with 5mm depron sheet covering.

Inside the fuselage are two ducted fans: a 90mm fan with two

dirigeable exhaust ducts, installed at the rear of the fuselage

near the CG (center of gravity), and a 70mm fan installed

towards the front of the fuselage, further away from the CG. The

ducted fan bases and motors are secured to the fuselage with

four long threaded screws. The outer layer is made and covered

by thin layer silver solar film to form the AV 9M

fuselage. The wings are attached to the fuselage with eight 4mm

screws. The rudder is larger than the original rudder and is

firmly attached to the fuselage |

|

|

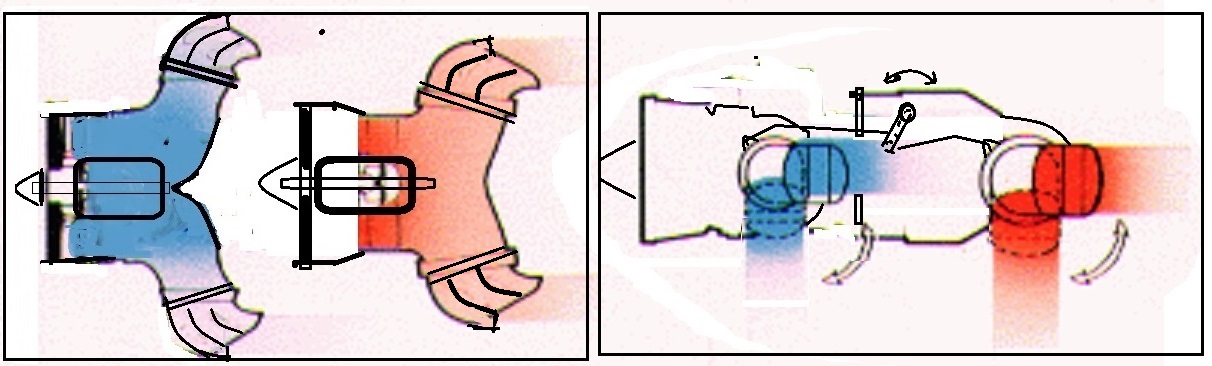

| The ducted fan , motor and

conduct exhaught dirigable pipe :

I use 90 mm ducted fan powered by one 2300W motor and

one 70mm ducted fan with brushless 1600w DC motor, ESC in

use are 120 and 100A with BEC 5v . The conduct pipe is forme by hard

0,2mm paper in form Y and reinforced by two layer fiberglass

compopsite ( sea pic ) .

An servos 13kg intalled to dirigeable syncronized the four

exhaust

pipe ( sea pic ) Two cell 3000mAh 45C Lipopolymer battery are intall

parallelic under the fuselage inbox in 30mm cannon box under the

fuselage .

Gear system : This is a sprintable and retractable

quadricycle gear : all contruction

are steel rod and aluminium tube ( see pic ) and this is the lightest

sprintable gear i had made ( see pic ) . The nose gear was

dirigable by an mini 1,5kg servos

R/C system , servo & other link installation :

Six 2,5kg mini servo for elevator , rudder , aileron and flap & one mini servo

for nose gear , two for stabilizer gear under the wing and one

10,5 kg servos for dirigeable exhaust pipe systeme .

. The two receiver

and the ESC are intall

fixed in high of the fuselage and adjust for the CG (

Center of gravity ) at 35%-40% from the front of the wing cross section . The

two receivers

was place on the highest of the fuselage in the pilot copit

and in the fuselage

Gyro and hover stabilizer systeme : I use a strong 12V

DC air-cooled mini fan to direct compressed air to the right

, left wingtip, and the rear tube to control the roll,

yaw, and pitch when the aircraft is hovering. An electronic gyro

system is installed to ensure stability when the aircraft hovers

in the air ( sea pic )

|

|

The rudder and elevator's rod are two 2/32 steel wire fixed

at the end ( see pic ) . These are light , hard and had

any trouble in working Rudder , elevator , aileron adjust & flying test : Up

3/4 and down 2/3 inch for elevator . Right 3/4 and lelf 3/4 for

rudder and 1/2 inch for the aileron . On the first fly ,

reduce some on the effect-angle of the aileron an elevator

and slight trim down on elevator ( on the first test flight ).

|

| On a

clear and calm sunday morning , I made my first flying test ...... |

|

Click

to see the

character , it hover and outdoor flying images |

___________________Back

to main page ___________________Back

to main page |

|

|

|

-My

home page I My

family home page I My

personal page I Medline

IR/C model airplane page

I Games

I Science

|

|

Add : Dr BUI BINH THO 35B Ho Hoa , To1 , Kp 1 , Tan Phong ,BIEN

HOA , DONG NAI , VIET NAM Email

:

buibinhtho52@gmail.com

Cpyright

© 2001: My homepage's Bui Binh Tho Md

, 35BHo Hoa, to1, Kp1, Tan Phong , BIEN HOA , DONG NAI , VIET NAM . Tel (0251) 8820217 ,

Mobile : 0903358597 . Plus ( +84 ) for all oversea relation .

All

Rights Reserved.

This document is strictly for informational, non-commercial purposes. |

|

__________________

__________________